In the depths of the ocean, silence has weight.

Every meter downward multiplies the pressure, until it becomes a force that can crush steel, deform glass, and collapse the most carefully built machines. Yet, in that cold and endless darkness, human beings still dare to explore — to send vessels, sensors, and sometimes even themselves into the unknown.

For such journeys, one question defines everything: what can survive the deep?

The Challenge of Pressure

Pressure is not a constant enemy; it’s a patient one. At 10,000 meters below sea level, it can exceed 1,000 times the atmospheric pressure on the surface. Every material — no matter how strong — eventually begins to yield.

Traditional alloys like aluminum lose stiffness, while steel, though strong, carries weight that limits buoyancy. Composite materials, admired for their lightness, often fail under uneven stress.

This is where titanium begins to stand apart. Not because it is simply stronger, but because it endures differently. Its balance of strength, lightness, and corrosion resistance makes it a rare survivor — not in theory, but in practice.

In the world beneath pressure, endurance matters more than brute strength.

The Science of Strength

Titanium’s strength does not come from sheer density, but from structure. Its atomic arrangement and stable oxide layer create a natural defense against both mechanical stress and chemical attack.

It has what engineers call a high strength-to-weight ratio: almost twice that of steel, yet only 60% of its weight. More importantly, it resists corrosion even in saltwater, where most metals begin to decay.

Alloys such as Ti-6Al-4V (TC4) and Ti-6Al-6V-2Sn combine these traits with fine-tuned elasticity, allowing hulls to flex slightly under pressure rather than fracture.

This combination — rigidity with resilience — is why titanium thrives in both deep-sea exploration and spacecraft design.

One metal, two extremes: from the ocean floor to the edge of the atmosphere.

Forging the Impossible

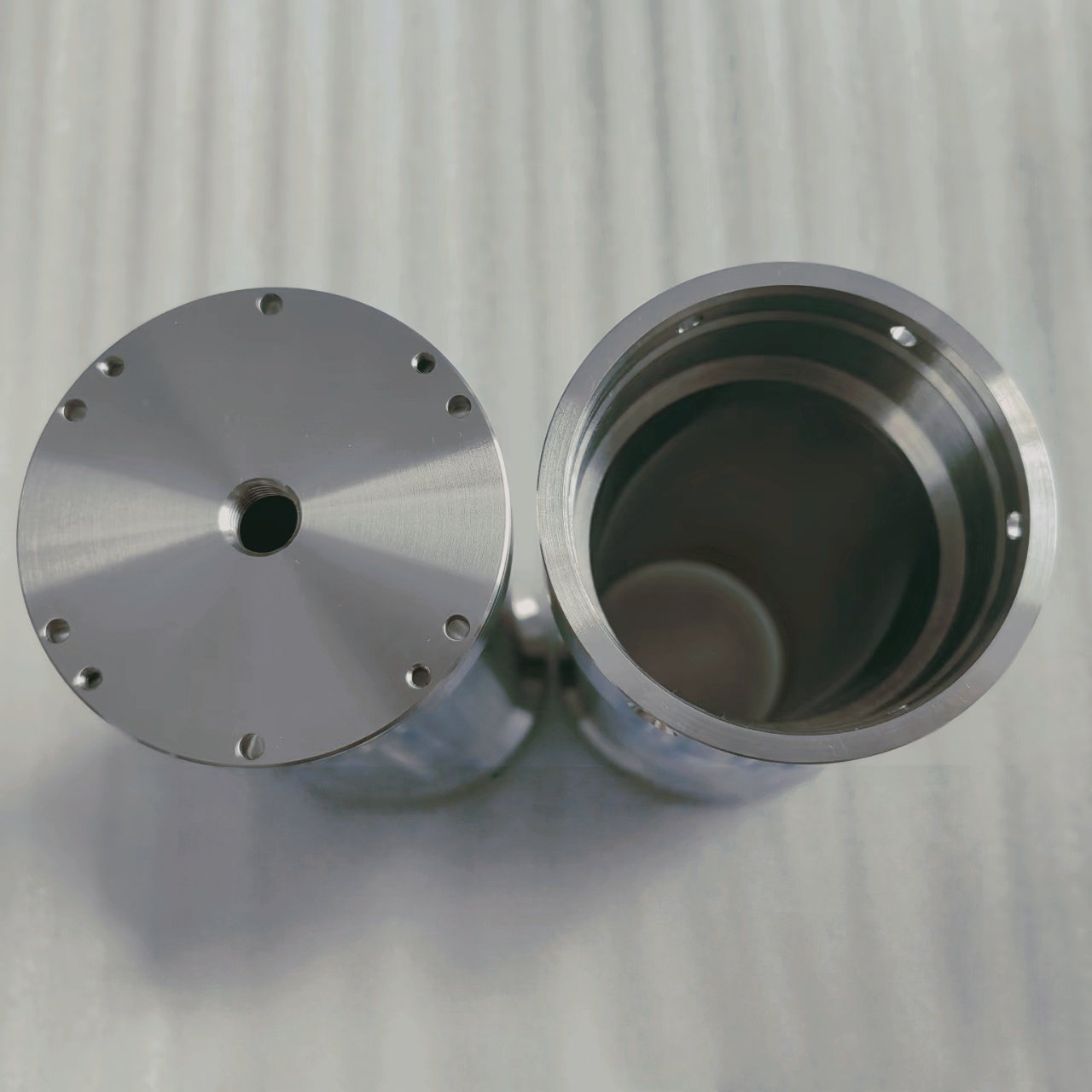

A titanium pressure hull does not come into being easily. It is not cast like steel or molded like plastic — it must be forged, shaped, and refined with near surgical precision.

Each section begins as a solid titanium ingot, heated and hammered under controlled temperature to align its microstructure. The halves of a submersible sphere, for instance, are later CNC-machined to tolerances measured in microns before being welded together.

Welding titanium is itself an art. Because the metal reacts with oxygen at high temperatures, it must be joined within a protective argon atmosphere, leaving no chance for contamination.

Every seam is then examined by ultrasonic or X-ray inspection — not once, but repeatedly.

Each weld is a silent promise: that inside this shell, pressure will never win.

From the Ocean to the Stars

Titanium’s story doesn’t stop at the seafloor. The same pressure-resistant properties that protect submersibles also serve in aerospace fuel systems, satellite frames, and chemical reactors.

In space, the challenge is not crushing pressure, but the opposite — a vacuum that can draw gases and fluids through microscopic flaws. Titanium’s stability ensures that it holds its form, no matter the direction of stress.

In chemical plants and hydrogen storage systems, it resists acids and halides that would corrode other metals.

Wherever the environment is too deep, too cold, or too reactive, titanium steps in — quietly doing what others cannot.

Sustainability Under Pressure

Engineering often measures success by performance, but endurance tells a deeper story.

A titanium pressure hull can operate for decades without replacement, its surface forming a self-healing oxide film that renews itself after every exposure.

The result is not only reliability but sustainability: fewer repairs, fewer replacements, and ultimately, less waste.

When its service life finally ends, titanium can be recycled indefinitely without losing its purity.

In an age that seeks balance between progress and preservation, titanium offers a simple truth —

the longest-lasting solutions are often the most responsible ones.

The Human Philosophy of Reliability

Behind every titanium shell lies a quiet philosophy of engineering.

Building something that can withstand immense pressure isn’t just about pushing technical boundaries — it’s about respecting life.

Every bolt, curve, and weld represents a calculation against failure, but also a declaration of faith: that human ingenuity can create safety where nature offers none.

This is why engineers often speak of titanium with reverence.

It’s not the flashiest metal, nor the easiest to shape, but it stands as a symbol of trust and endurance — proof that precision, when guided by purpose, becomes more than a craft.

It becomes a safeguard.

Forged for the Deep

To design a hull from titanium is to design for the impossible.

It must endure crushing forces, endless saltwater, and the weight of the unknown. Yet when it does, it allows humanity to go further — to explore trenches, harvest clean energy, or gaze at the stars.

Titanium doesn’t just survive pressure; it carries our courage beneath it.

In the quiet between strength and stillness, it reminds us why we build — not merely to resist, but to reach.