ISO certification is everywhere. Scroll through any titanium supplier’s website and you’ll probably find a shiny “ISO 9001 Certified” badge sitting proudly on the homepage. But what does that really mean? More importantly—does it mean anything useful to you as a titanium buyer?

In international titanium sourcing, certifications are often the first thing buyers check—and the last thing they truly understand. Some see them as a bureaucratic checkbox. Others mistake them for a guarantee of product performance. And some simply collect logos without ever looking beyond the surface.

But if you're sourcing titanium for critical applications—whether it's titanium bars for machining, plates for pressure equipment, or medical-grade rods for implants—then understanding certifications is more than helpful. It’s essential.

In this article, we’ll cut through the confusion and focus on what ISO certifications actually say about a titanium factory, how they relate to different product categories, and how you can read between the lines when a supplier says, “We’re certified.”

1. ISO 9001: The Quality System Behind the Titanium

Let’s start with the most common one—ISO 9001. If your supplier claims to be ISO 9001 certified, that’s generally a good sign. It means their production isn’t a free-for-all, but instead follows a documented, traceable, and auditable quality management system.

But what ISO 9001 doesn’t mean is this:

It doesn’t mean your titanium bar meets ASTM B348.

It doesn’t mean your titanium tube passed ultrasonic testing.

It doesn’t mean your final machining won’t uncover internal defects.

What it does mean is that the supplier has systems in place to help catch mistakes before they happen. For bulk orders of titanium rods, tubes, plates, or flanges, this kind of internal discipline matters—especially if you want consistent quality over multiple batches.

In practice, ISO 9001 helps ensure that what you receive in June won’t be drastically different from what you got in February—even if you didn’t ask a hundred questions every time.

In high-volume, ongoing titanium sourcing relationships, that kind of predictability can save you time, money, and serious frustration.

2. ISO 13485: Medical-Grade Titanium Needs More Than Clean Hands

Now let’s raise the bar. If your product is going into a human body, ISO 9001 simply isn’t enough.

ISO 13485 is the globally recognized standard for medical device manufacturing—and yes, that includes titanium implants, bone screws, spinal cages, and dental prosthetics. It covers everything ISO 9001 does, but adds requirements around:

- Risk management

- Process validation

- Biocompatibility assurance

- Full traceability of every batch and tool

This is especially relevant when working with ASTM F136 or F67 grade titanium, which are used in implantable parts. Without ISO 13485, even the best titanium might get rejected in audits, registrations, or regulatory submissions.

A supplier without ISO 13485 can still sell titanium bars. But if you're producing a Class II or Class III medical device, using uncertified material could cost you far more than you save.

Think of ISO 13485 as the minimum ticket to enter the world of serious medical-grade titanium.

3. AS9100: When Titanium Takes Flight

Next stop: aerospace. In this sector, traceability isn't just appreciated—it’s non-negotiable. That’s where AS9100 comes in. It’s built on ISO 9001 but adds aerospace-specific controls like:

- Process risk management

- Product conformity planning

- Supplier qualification systems

If you’re sourcing titanium for:

- Aircraft brackets

- Engine fasteners

- Aerospace fittings made from AMS 4928 or AMS 4911 titanium

...then AS9100 certification from the supplier is often a precondition to even be considered for the project.

It tells you that the supplier understands what’s at stake in flight-critical applications—and has the systems to support it.

Without AS9100, you might still get titanium—but you probably won’t get it on board.

4. So… Are They Really Certified? Or Just Certified-ish?

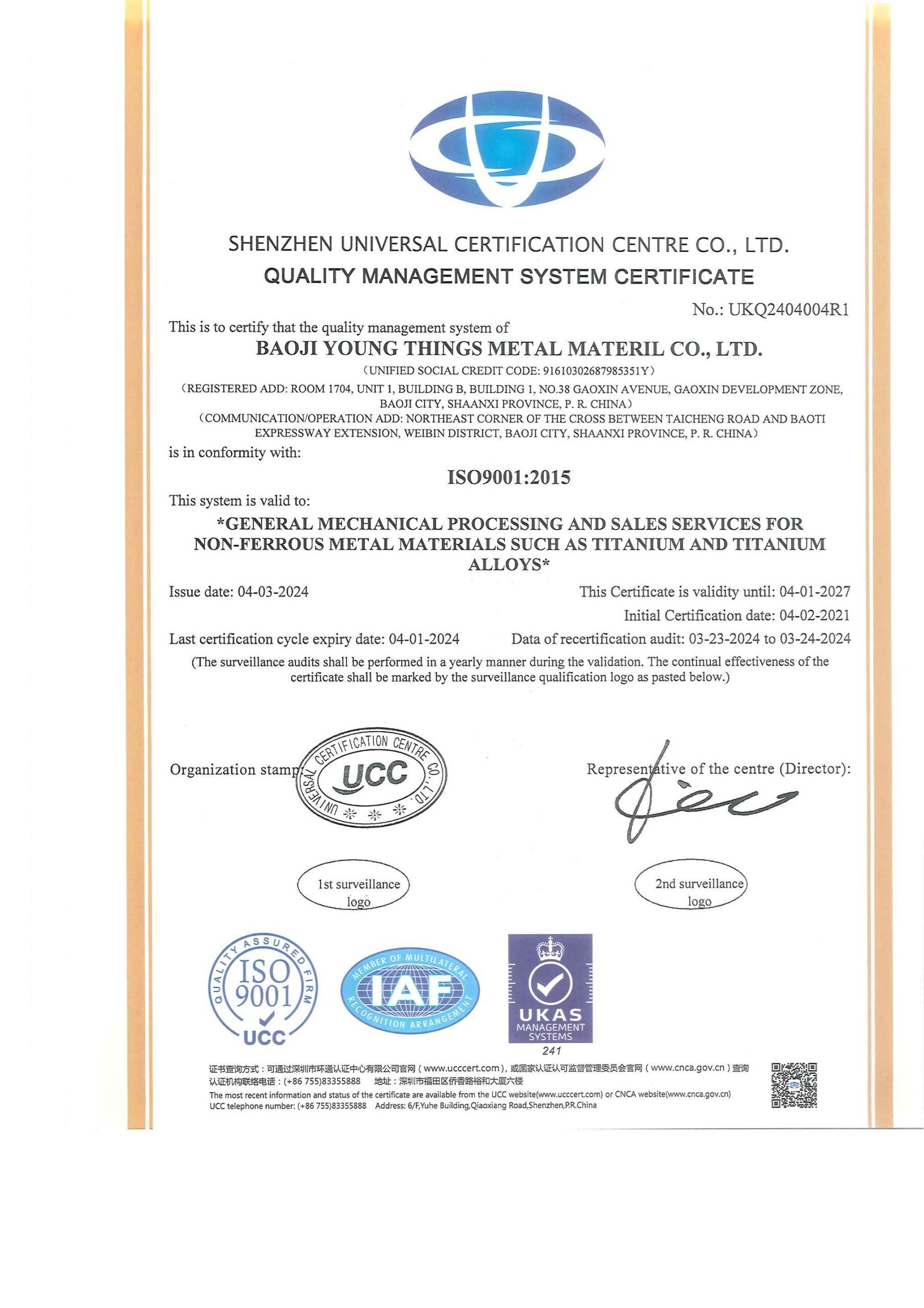

We’ve all seen it—suppliers claiming to be “certified” with logos that look good but say nothing. Here are a few tips to separate fact from fluff:

- Check the certificate issuer – Is it an accredited body like TÜV, SGS, or DNV? Or a no-name printer?

- Verify the scope – Does the certificate cover “titanium manufacturing,” or just “metal trading”?

- Look at expiration dates – Is the certificate still valid?

And yes, it’s perfectly okay to ask for the PDF. Serious suppliers will provide it immediately—and proudly.

Because real certification isn’t just for show. It’s the foundation of trust in every titanium delivery that follows.

Final Thought: ISO Is Not Everything—But It’s a Good Start

Let’s be clear: ISO certification doesn’t replace technical standards like ASTM B348 or PED approval. It won’t ensure your titanium forging is defect-free. But it does tell you how the factory thinks, operates, and corrects itself when mistakes happen.

In a world of tight timelines, demanding specs, and global regulations, having the right ISO system behind your titanium supplier isn’t just comforting—it’s a competitive advantage.

So the next time you see “ISO certified” on a website or quotation, don’t just accept it blindly. Ask the right questions. Read the scope. Understand what it means for your product—and what it doesn’t.

Because in the world of titanium, you’re not just buying metal.

You’re buying the system that makes it reliable.

Share this article

Written by : 钛合金网

Follow us

Table Of Content