When purchasing titanium bars or billets, it’s common to come across the term “ASTM B348.” But unless you're familiar with technical standards, it's easy to misunderstand what this actually means—or to assume it's just a formality. In reality, ASTM B348 plays a key role in ensuring the reliability, traceability, and performance of titanium materials.

Whether you're sourcing titanium for aerospace, chemical processing, or medical use, understanding this standard can help you make better procurement decisions. Here's what every titanium buyer should know.

1. Understanding the Role of ASTM Standards in Titanium Procurement

ASTM International (originally the American Society for Testing and Materials) is a globally recognized organization that publishes thousands of material and testing standards. These standards form the technical foundation for material production and trade in many industries, including metals, plastics, construction, and healthcare.

In the titanium industry, ASTM standards help define:

- Material grades and chemical composition

- Mechanical property requirements

- Dimensional tolerances

- Testing and certification expectations

When a buyer requests titanium rods "according to ASTM B348," they are referring to one specific standard—but it's just one among many. For example:

- ASTM B265 covers titanium plates and sheets

- ASTM B381 applies to titanium forgings

- ASTM F67 defines commercially pure titanium for surgical implants

Each of these serves a different form and application of titanium.

Today’s article focuses on ASTM B348, which is the most relevant for those purchasing titanium bars and billets. But knowing these related standards can help you make better-informed decisions across different product forms.

2. Breaking Down ASTM B348: Scope, Material Grades, and Mechanical Properties

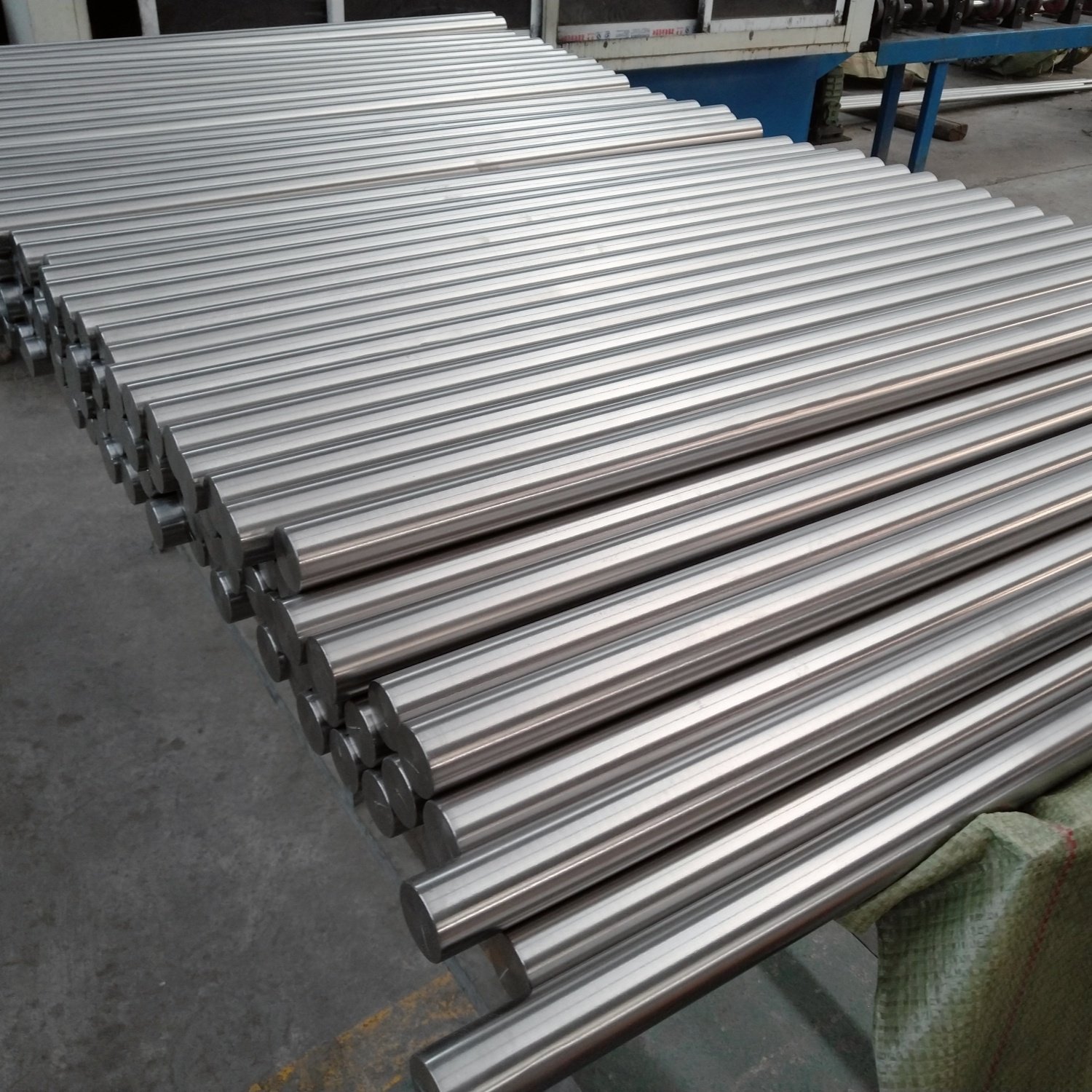

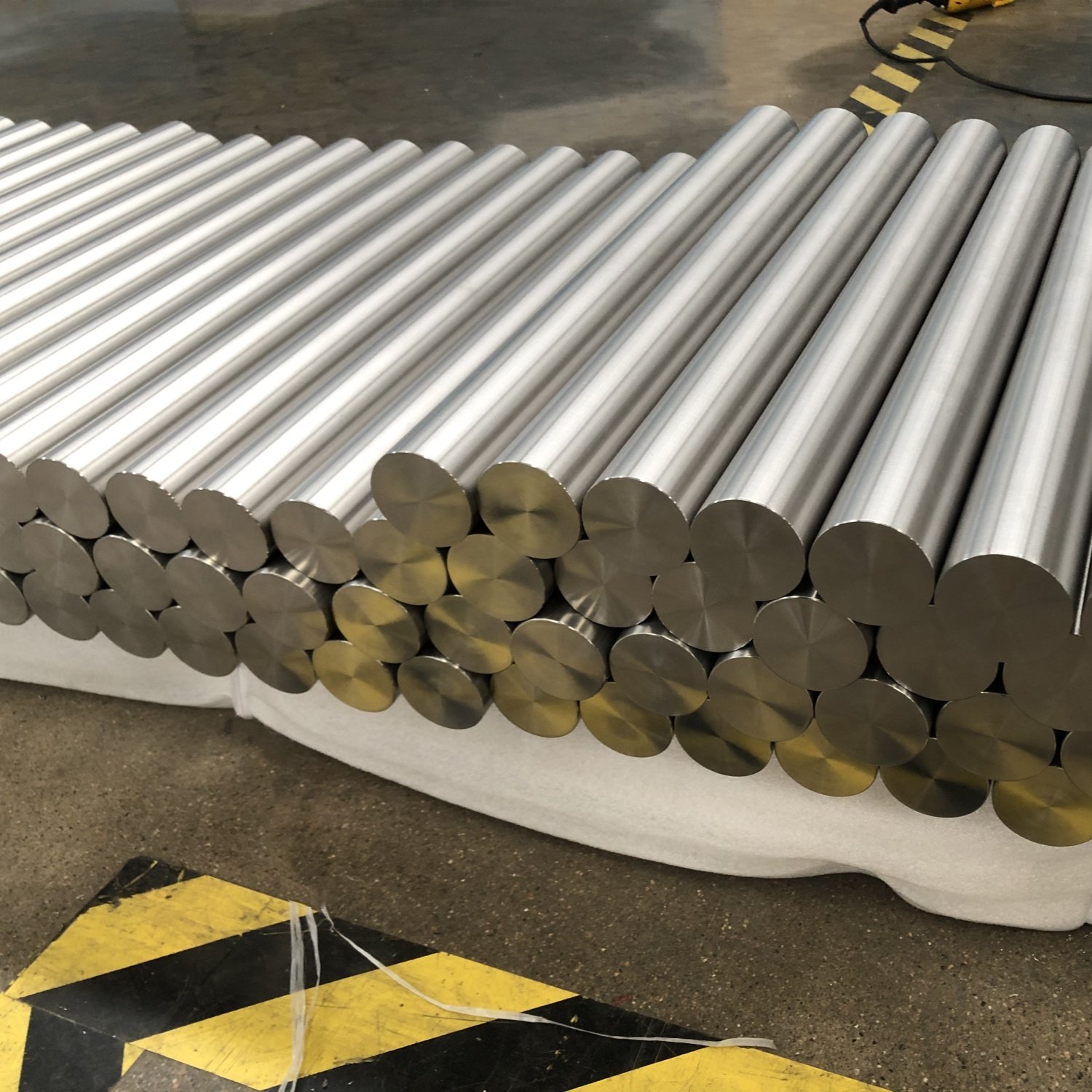

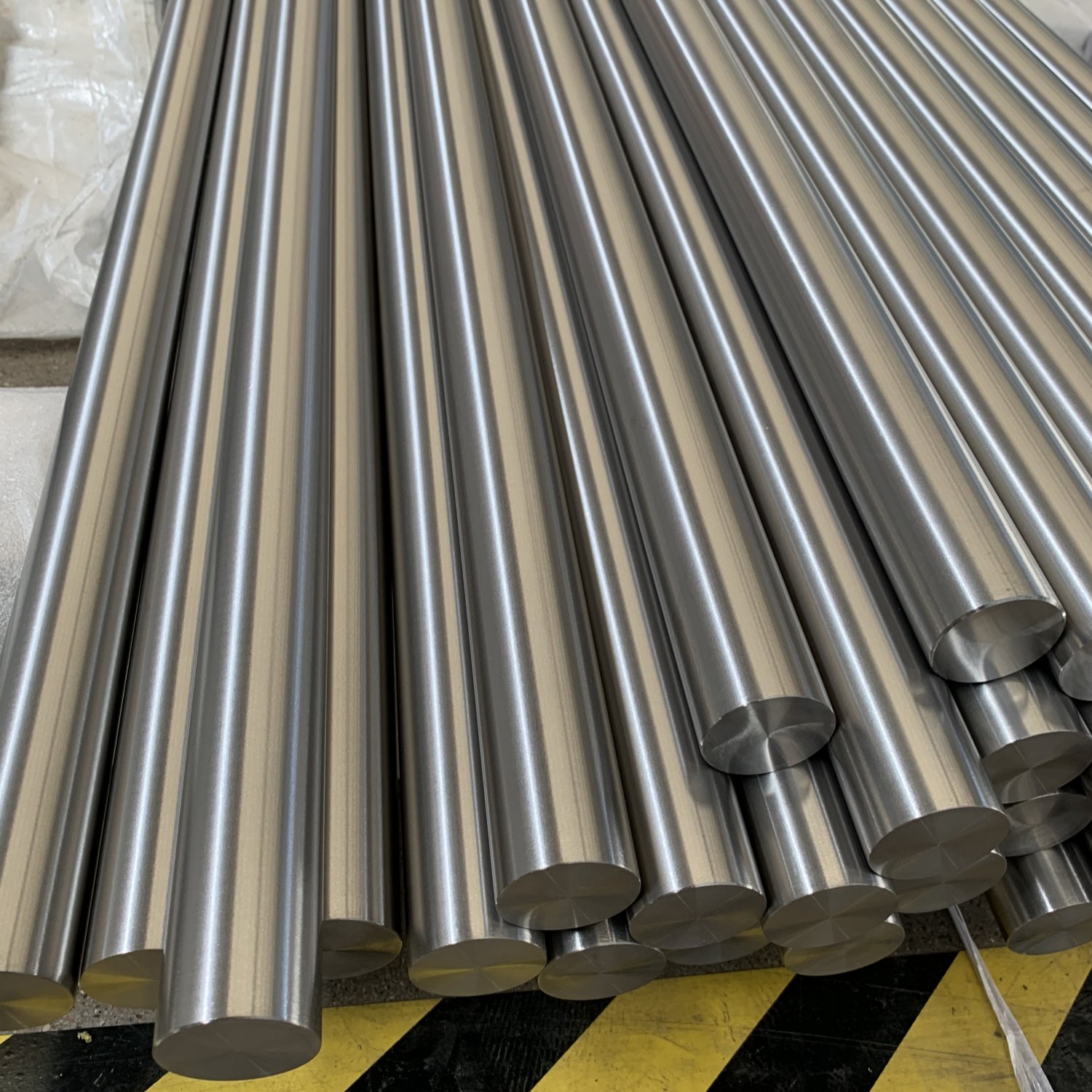

ASTM B348 is the standard specification for Titanium and Titanium Alloy Bars and Billets. It applies to forged or rolled products in straight lengths, typically used as raw material for further machining or processing.

Among these, titanium bars (commonly referred to as "titanium rods") are the most widely purchased and applied product under this standard. They are essential for industries requiring round or square profiles that can be further machined into fasteners, shafts, components, or implants.

The Grades

The standard includes both commercially pure titanium (Grades 1 to 4) and titanium alloys, such as:

- Grade 5 (Ti-6Al-4V): High strength, widely used in aerospace and medical applications

- Grade 2: Good corrosion resistance, often used in chemical and marine applications

- Grade 23 (Ti-6Al-4V ELI): A purer form of Grade 5 for surgical implants and medical parts

Mechanical Property Requirements

Each grade under ASTM B348 comes with defined performance benchmarks:

- Tensile Strength

- Yield Strength

- Elongation (%)

- Reduction of Area (%)

These properties ensure the material can perform reliably under specific working conditions, whether it's structural support or chemical containment.

For titanium bars, mechanical properties are especially critical because they are often subjected to further machining or load-bearing conditions. Any deviation in these properties can directly affect the strength, fatigue resistance, and overall performance of the final part.

3. Quality Requirements Beyond the Surface: Dimensions, Tolerances, and Testing Methods

Compliance with ASTM B348 doesn’t stop at the material’s composition—it also ensures that bars meet strict dimensional and surface standards.

Dimensional Tolerances

- Straightness, diameter, and roundness are controlled within specific tolerances, depending on whether the bars are hot rolled, cold drawn, ground, or polished.

Titanium bars used for precision components (such as fasteners or orthopedic screws) often require tighter dimensional tolerances and smoother surface finishes. The standard allows for various processing methods like centerless grinding or polishing to meet these needs.

Surface Condition

-

Minor surface defects like oxide layers or scratches may be allowed unless otherwise specified.

-

However, surface quality becomes critical for aerospace or medical applications.

Testing & Inspection

-

Ultrasonic testing may be required for detecting internal flaws, especially in high-spec industries.

-

Additional tests like chemical analysis, mechanical testing, and hardness checks are typically included in mill test reports.

For titanium bars intended for machining or welding, ultrasonic testing (UT) is commonly required to ensure there are no hidden internal voids or cracks that could lead to failure during processing. This is particularly vital for medical, petrochemical, or structural applications.

For certain applications, ASTM B348 may be used alongside more stringent standards—like AMS 4928 for aerospace bar stock, or ASTM F136 for medical-grade alloy bars—depending on end-use requirements.

4. How to Specify ASTM B348 Correctly in Your Orders

Simply writing “ASTM B348 titanium rod” on a purchase order leaves room for confusion. A good specification helps prevent mistakes and reduces back-and-forth communication with suppliers.

Be Specific About:

- Grade: e.g., Grade 2, Grade 5 (Ti-6Al-4V), or Grade 23

- Dimensions and Finish: Diameter, length, surface condition (peeled, ground, polished)

- Test Requirements: Whether you require ultrasonic testing or mechanical property verification

- Certification: Request a mill test report (MTR) or EN10204 3.1 certificate if traceability is important

- Application Notes: If the bars are intended for machining, welding, or use in critical environments, it’s worth including that too.

Sample Specification

“Titanium bar, Grade 5 (Ti-6Al-4V), 20mm diameter x 3000mm length, ASTM B348, polished surface, ultrasonic tested, supplied with EN10204 3.1 certificate.”

Clear documentation ensures your supplier delivers the material exactly as you need it—and gives you peace of mind during production.

Conclusion: More Than a Code—A Trust Framework

ASTM B348 isn’t just a code—it’s a shared understanding between buyer and supplier. It guarantees that titanium bars meet expected chemical, mechanical, and dimensional requirements, and it provides a foundation for traceable, certifiable quality.

Among all forms of titanium mill products, titanium bars are perhaps the most universally used, making ASTM B348 one of the most frequently referenced standards in the industry. Whether you're sourcing round rods for CNC machining, forged bars for aerospace parts, or straight lengths for structural components, this standard is your technical baseline.

If you're dealing with other titanium forms like sheets, forgings, or medical implants, it's also worth learning about related standards like ASTM B265, B381, F136, or F67.

But if you’re focused on titanium bars, start by mastering ASTM B348. It’s your best ally for risk-free sourcing, especially when consistency, compliance, and performance really matter.

Share this article

Written by : 钛合金网

2 Comments

Leave A Comment

Follow us

Table Of Content

- 1. Understanding the Role of ASTM Standards in Titanium Procurement

- 2. Breaking Down ASTM B348: Scope, Material Grades, and Mechanical Properties

- 3. Quality Requirements Beyond the Surface: Dimensions, Tolerances, and Testing Methods

- 4. How to Specify ASTM B348 Correctly in Your Orders

- Conclusion: More Than a Code—A Trust Framework

Great article explaining the importance of ASTM B348 for titanium procurement! It’s crucial to have these standards for material reliability, especially in critical applications like medical implants.

This got me thinking about standards in other industries, particularly pharmaceuticals. For a project, I’m researching the composition and international equivalents of various vitamin complexes. I came across a formulation called “Ultra B” which seems to contain Thiamine and Pyridoxine.

Does anyone here have experience with how international pharmaceutical standards (like USP or EP) for such vitamin complexes compare to the rigorous material standards we see in ASTM for titanium? Specifically, I’m trying to understand the equivalency and regulatory acceptance of a product like https://pillintrip.com/medicine/ultra-b in different markets. Any insights would be appreciated!

Thank you for your comment and for raising such an interesting point. Indeed, ASTM standards like B348 and pharmaceutical standards such as USP and EP share a common goal — ensuring product consistency and safety across industries. While ASTM governs material reliability for applications like titanium components, pharmacopoeial standards ensure the quality and efficacy of active ingredients such as Thiamine and Pyridoxine.

It’s great to see this cross-industry perspective — we appreciate your insight and would love to hear more about your research on international vitamin formulations.