Titanium has a reputation for being a rockstar in engineering—strong, lightweight, corrosion-resistant. But here’s the thing: even rockstars have weak spots. If you're working with titanium alloys or sourcing titanium components, it pays to know what could go wrong beneath the surface.

Yes, titanium is tough. But it's not invincible. Contamination, heat treatment missteps, or hidden flaws like porosity can seriously reduce its toughness and fatigue life—making inspection and process control absolutely essential.

Titanium is impressive, no doubt. But as someone who's spent plenty of time around it, I can tell you—it’s got its quirks. Let’s dig into the less glamorous side of this supermetal.

So What’s Titanium Actually Vulnerable To?

Titanium looks bulletproof on paper—resists corrosion, holds up at high temps. But put it in the wrong environment or process it carelessly, and cracks (sometimes literal ones) start to show.

The biggest culprits? Oxygen, hydrogen, nitrogen, high heat, and poor processing decisions. Left unchecked, these can turn a solid part into a ticking time bomb.

Real-World Weaknesses

-

Interstitial Embrittlement — Tiny Atoms, Big Trouble

Titanium loves picking up small atoms—oxygen, nitrogen, and hydrogen—especially when it’s hot.- Oxygen & Nitrogen: During forging or heat treatment without inert shielding, these elements form a brittle surface layer known as alpha case. It's hard, it's fragile, and it loves to crack.

- Hydrogen: This one’s sneaky. It can sneak in during pickling or welding, and later cause unexpected cracking. True story: one client had titanium fasteners that looked great… until they started cracking weeks after installation. Turned out the pickling bath introduced hydrogen.

-

Heat Sensitivity — Don't Crank the Temp

Overheating titanium? Bad idea. It leads to coarse grains and weakens the material. And if you're heating it in air? Congrats, you’ve just created alpha case. -

Crevice Corrosion — Trouble in Tight Spaces

While titanium laughs at general corrosion, it struggles in small, stagnant spaces—like under bolt heads or gaskets—especially in chloride-rich environments. The result? Localized corrosion that can sneak up on you. -

Galling — Titanium vs. Titanium = Ouch

Ever tried screwing titanium against titanium? It can seize up fast. This adhesive wear is common without the right coatings or lubricants. Definitely not a fun discovery during assembly.

The bottom line? Knowing these pitfalls helps you avoid costly surprises—both on the shop floor and in the field.

The Good, the Bad, and the Pricey: Titanium's Strengths and Trade-offs

No material is perfect. Titanium brings some amazing perks to the table, but it also comes with a few "quirks" that need careful handling.

What’s to love? Strength-to-weight ratio, corrosion resistance, biocompatibility. What’s the catch? High cost, tricky machining, and a tendency to misbehave at high heat.

Why Engineers Love It (And Sometimes Hate It)

Top Perks:

- Featherweight Power: Titanium is as strong as many steels but 45% lighter. That’s why planes and racing cars love it.

- Corrosion Resistance: It shrugs off seawater and harsh chemicals thanks to its natural oxide layer.

- Biocompatibility: It plays nice with the human body, making it perfect for implants.

- Heat Performance: Titanium alloys keep their cool at high temps, outperforming aluminum by a mile.

But Here’s the Catch:

- It’s Expensive: From mining to machining, titanium is energy-hungry and labor-intensive.

- Machining Is a Pain: It’s hard on tools, heats up fast, and likes to stick to cutting surfaces. Think special tools, coolants, and lots of patience.

- Not So Stiff: Compared to steel, it’s more flexible. That means parts might deflect more under load—a key design consideration.

-

High-Temp Diva: Above 400°C, it starts reacting with air unless you shield it properly.

Property What’s Great What to Watch For Strength/Weight Outstanding for lightweight designs – Corrosion Resistance Excellent in most environments Vulnerable to crevice corrosion Biocompatibility Safe for implants – Heat Tolerance Up to 600°C for some alloys Reactive above ~400°C without shielding Machinability – Tough to cut, needs special techniques Cost – High across the board Stiffness – Less stiff than steel

Picking titanium is often a trade-off—stellar performance vs. higher cost and manufacturing complexity.

Welding Titanium: Beautiful When Done Right, Brutal When It’s Not

Welding titanium can deliver amazing results—if you do it right. But mess it up, and you’re looking at a brittle, discolored, cracked mess.

The biggest enemy? Air. Oxygen, nitrogen, and hydrogen will ruin your weld faster than you can say “argon purge.”

Welding War Stories (And How to Avoid Them)

- Air Is the Enemy: Molten titanium sucks in gases from the air. Oxygen and nitrogen embrittle the weld; hydrogen causes porosity and delayed cracking.

- Shield Everything: Not just the weld pool. The cooling weld bead and even the backside need shielding.

- Torch shielding: Argon is your best friend.

- Trailing shields: Protects the weld as you move.

- Back purge: Shields the root side.

- Glovebox welding: For critical parts, it’s worth the hassle.

- Cleanliness Is Mandatory: Any oil, oxide, or moisture can spell disaster. Prep the parts thoroughly.

We always tell clients: skimping on shielding will cost you—if not now, then when the part fails in the field.

Defect Watch: What Can Go Wrong With Titanium Parts?

Even with good material, things can go sideways during processing. Some defects are invisible until it’s too late.

Watch out for: alpha case, hard alpha inclusions, porosity, elemental segregation, surface cracks, and heat treatment mistakes.

Real-World Defects That Matter

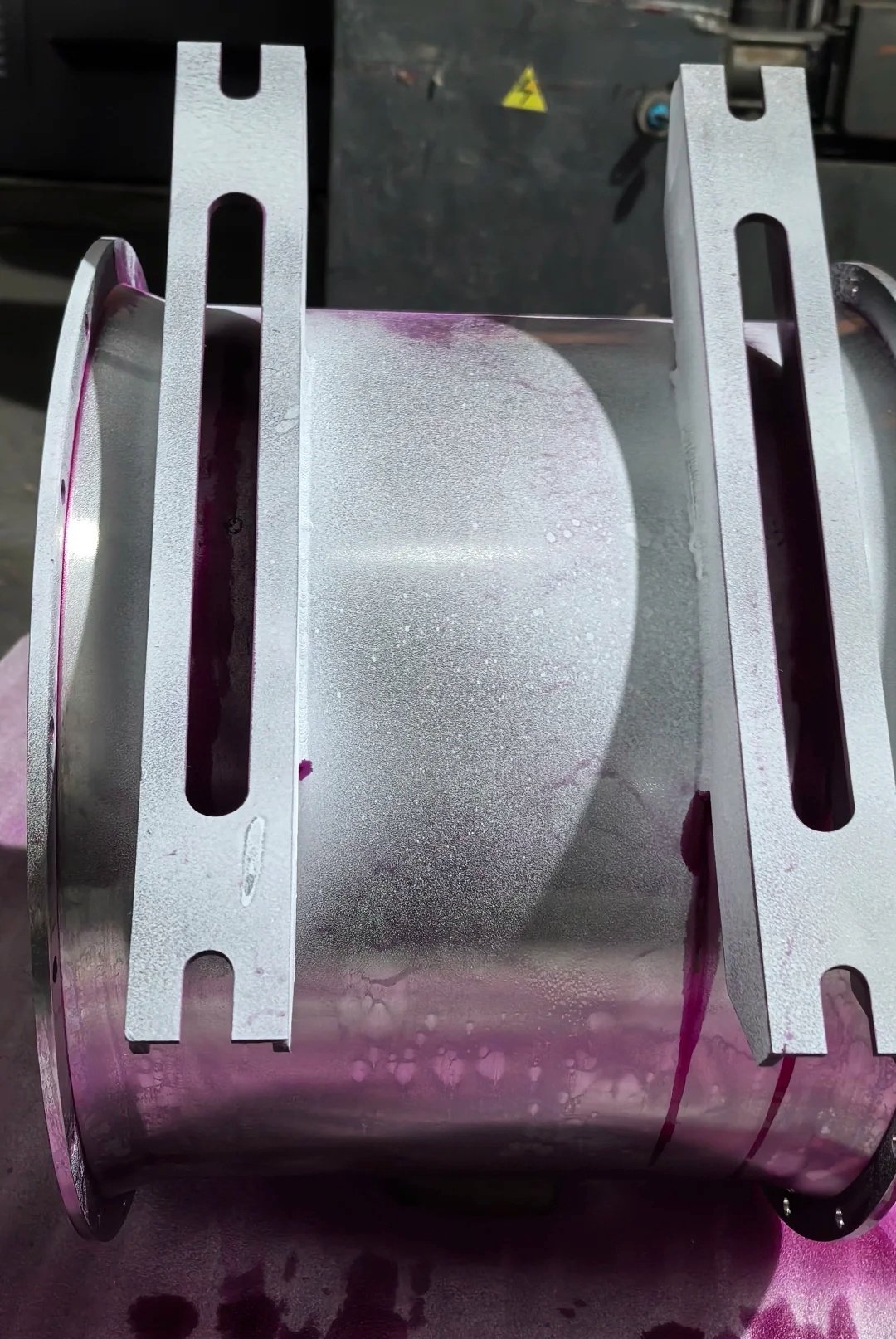

- Alpha Case: Brittle oxygen-rich surface from high-temp exposure. Machining or chemical milling usually needed to remove it.

- Hard Alpha Inclusions: Brittle, nitrogen-rich zones that can trigger cracks—especially dangerous in aerospace components. Ultrasonic testing is a must.

- Porosity: Gas trapped during melting or welding forms voids, weakening the structure.

- Segregation: Uneven distribution of alloying elements (like Al or V in Ti-6Al-4V) causes inconsistent mechanical properties.

- Cracks & Surface Defects: Often introduced during forging or aggressive machining.

- Heat Treatment Errors:

- Overheating? You’ll get coarse grains and lost toughness.

- Incomplete aging? Missed your strength targets.

- Bad quenching? Expect residual stresses and distortion.

That’s why solid process control and rigorous NDT—ultrasonic, X-ray, dye penetrant—are critical before anything ships out the door.

Final Thoughts: Respect the Metal

Titanium is an incredible material, but it demands respect. When treated right, it delivers performance that few materials can match. But if you cut corners—on shielding, machining, or inspections—it’ll come back to bite you.

Think of titanium like a high-performance machine: amazing when tuned correctly, but unforgiving when neglected. Handle it with care, and it’ll reward you with lightweight strength, reliability, and long-term value.

Let me know if you'd like to go deeper into quality control methods or any specific defect mechanisms—we've seen plenty of them in real-world projects!