Your machine shop loses $5,000 every time a titanium part gets scrapped. Why does this strong metal break tools and budgets so easily?

Titanium's high strength and low thermal conductivity cause rapid tool wear, heat buildup, and work hardening. Specialized tool geometries, coatings, and cutting parameters are essential for successful machining.

Let's examine why titanium behaves differently than steel and how to overcome these challenges.

What Are the Challenges of Titanium Machining?

Watch any machinist's face when you mention titanium - that grimace tells the whole story. What makes this metal so difficult?

Titanium combines four problematic properties: high strength at temperature, low thermal conductivity, chemical reactivity, and elastic modulus. This creates tool wear, heat retention, and part deflection issues.

The Titanium Machining Problem Matrix

| Challenge | Cause | Consequence | Solution Approach |

|---|---|---|---|

| Rapid tool wear | Titanium's strength maintains hardness at machining temps | Frequent tool changes | Cobalt or carbide tools with specialized coatings |

| Heat buildup | Low thermal conductivity (7 W/m·K vs 50 for steel) | Workpiece warping, tool degradation | Increased coolant pressure (1000+ psi) |

| Work hardening | Titanium's tendency to deform rather than shear | Tool breakage, poor finish | Maintain consistent chip load |

| Long chips | Ductility causes stringy swarf | Safety hazard, re-cutting | Chip breakers and high-pressure coolant |

| Part springback | Low modulus of elasticity (110 GPa vs 200 for steel) | Dimensional inaccuracy | Multi-pass finishing strategies |

What Is the Best Titanium Alloy for Machining?

Not all titanium alloys fight your tools equally. Which grades cooperate better in machining?

Grade 5 (Ti-6Al-4V) balances machinability and performance, while Grade 2 offers easier cutting but less strength. Special alloys like Ti-5553 require advanced tooling strategies.

Machinability Comparison of Common Alloys

Grade 2 (CP Titanium)

- Relative Machinability: 40% (compared to free-cutting steel)

- Best For: Simple parts with high corrosion needs

- Tool Life: 2-3x longer than Grade 5

- Key Limitation: Lower strength limits applications

Grade 5 (Ti-6Al-4V) - Relative Machinability: 20%

- Best For: Structural aerospace components

- Cutting Speed: 30-50 m/min for roughing

- Special Requirement: Needs sharp tools with positive rake angles

Grade 23 (Ti-6Al-4V ELI) - Relative Machinability: 18%

- Medical Industry Standard: Required for implants

- Critical Need: Avoid contamination during machining

Ti-5Al-5Mo-5V-3Cr - Relative Machinability: 15%

- Aerospace Challenge: Highest strength-to-weight

- Solution: Cubic Boron Nitride (CBN) tooling required

What Is the Hardest Metal to Machine?

Titanium ruins tools quickly, but it's not the worst offender. What metals make machinists lose sleep?

While titanium is challenging, nickel alloys like Inconel 718 and hardened steels surpass it in difficulty due to extreme hardness and work hardening tendencies.Metal Machining Difficulty Ranking

- Nickel-Based Superalloys (Inconel 718)

- Hardness: 45 HRC

- Key Challenge: Maintains strength at 700°C

- Tool Life: 1/5th of titanium machining

- Hardened Tool Steels (D2, M2)

- Hardness: 60+ HRC

- Solution: Requires ceramic or CBN tooling

- Titanium Alloys (Ti-6Al-4V)

- Unique Problem: Heat concentrates in tool

- Stainless Steels (304, 316)

- Issue: Work hardening during cutting

Titanium vs. Other Metals - Cutting Data Comparison

- Issue: Work hardening during cutting

- Nickel-Based Superalloys (Inconel 718)

| Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Tool Material |

|---|---|---|---|

| Aluminum 6061 | 300-1000 | 0.1-0.5 | HSS or Carbide |

| Mild Steel | 150-250 | 0.2-0.4 | Coated Carbide |

| Stainless 304 | 60-120 | 0.1-0.3 | Special Grades |

| Titanium Grade 5 | 30-50 | 0.08-0.15 | Carbide with TiAlN coating |

| Inconel 718 | 15-30 | 0.05-0.12 | Ceramic or CBN |

Conclusion

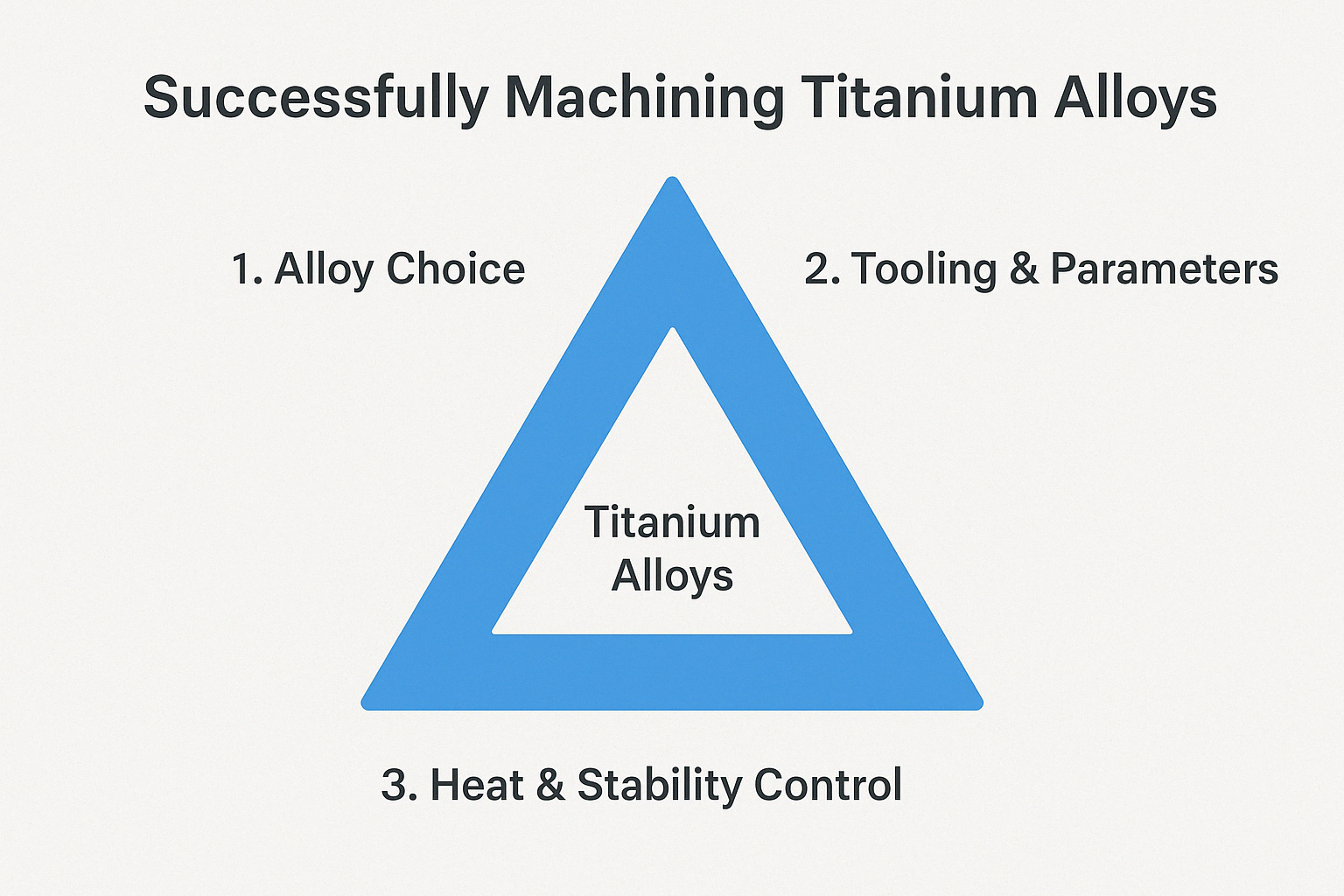

Titanium demands respect in machining - the right alloy choice, tool technology, and cutting strategy transform this challenging material into manufacturing success.

Share this article

Written by : 钛合金网

Follow us

Table Of Content