Hi everyone, this is Aria. Today, I’d like to dive into a critical technology in titanium and titanium alloy processing—CNC precision machining. CNC plays a vital role in manufacturing customized titanium parts, especially when complex shapes and tight tolerances are involved. In short, CNC (Computer Numerical Control) equips traditional machining tools—like lathes, mills, drills, and borers—with a smart “brain,” enabling them to perform tasks automatically and with high precision. Let’s explore how CNC technology efficiently processes titanium alloys and supports their use across various industries.

Titanium Alloys: High Performance Meets High Machining Difficulty

Titanium alloys are widely recognized as difficult-to-machine materials due to their unique physical and chemical properties. Their poor thermal conductivity causes heat to build up at the cutting edge during machining, leading to tool overheating, accelerated wear, or even burning. In addition, titanium’s high chemical reactivity at elevated temperatures promotes bonding with cutting tools, forming built-up edges that reduce surface quality. Its low modulus of elasticity results in elastic spring-back, complicating dimensional control. Moreover, titanium tends to work harden, making the machined surface harder and more resistant to subsequent operations. These characteristics often render traditional machining methods inefficient, imprecise, or prone to high scrap rates.

CNC Precision Machining: A Solution Built on Control

CNC machining offers a powerful solution to these challenges, thanks to its precision, consistency, and automation. Through programmed instructions, CNC controls tool path, cutting speed, feed rate, coolant delivery, and more—down to the finest detail. For example, to mitigate titanium’s poor thermal conductivity, CNC machines adopt low-speed, high-feed strategies paired with high-pressure, high-flow coolant systems to reduce cutting zone temperatures and prolong tool life. To deal with elastic rebound, optimized tool paths, sharp cutting edges, and constant cutting forces help minimize deformation and maintain dimensional accuracy. CNC also excels in consistency—once programmed correctly, it can reproduce the same part with incredible accuracy, ensuring stability in batch production.

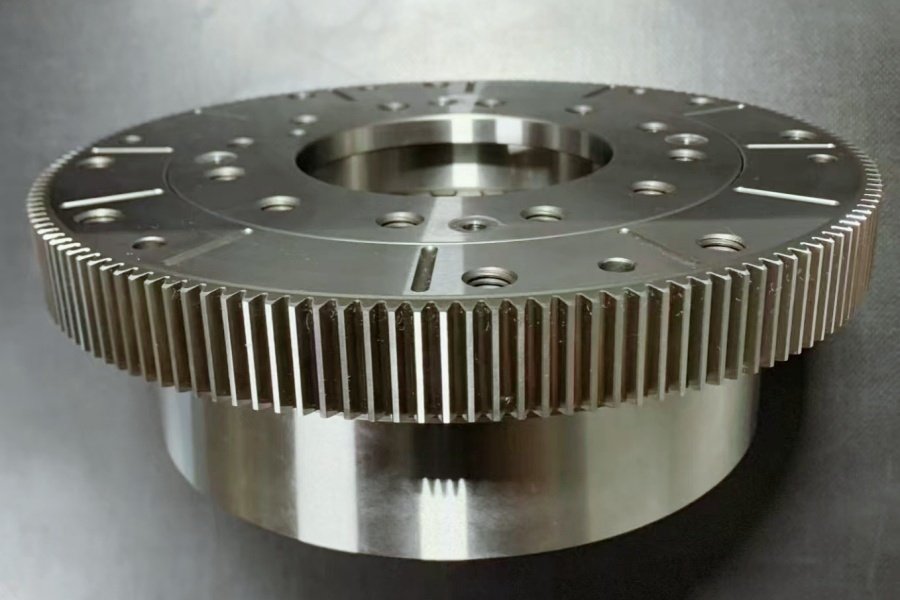

Precision Shaping: Mastering Complex Geometry

CNC machines—especially those with 3-axis, 4-axis, or even 5-axis capabilities—are ideal for crafting intricate geometries. Titanium’s performance benefits often lead to designs featuring complex, lightweight structures, such as turbine blades and integrally bladed rotors in aerospace, or anatomically contoured implants in medical applications. These shapes are challenging or uneconomical to produce with traditional methods. With multi-axis CNC systems, tools can move freely in 3D space, performing complex surface milling, angled hole drilling, and cavity finishing with ease—bringing engineers’ designs to life with remarkable fidelity.

Broad Industrial Applications

The advantages of CNC precision machining have made it a cornerstone in many advanced industries, especially aerospace, medical, industrial, and high-end consumer sectors.

In aerospace, CNC machining of titanium is a key technology. Aircraft structural parts—such as fuselage frames, beams, and landing gear components—as well as hot-section engine parts like turbine disks, blades, and combustor hardware demand tight tolerances, reliable performance, and excellent material properties. Titanium’s strength, low weight, and corrosion resistance make it a top choice, while CNC ensures the precise shaping and tolerance control necessary for high-performance aircraft.

In medical applications, CNC machining is essential for producing high-precision implants. Titanium’s biocompatibility makes it a popular material for artificial joints, spinal fixation systems, dental implants, and precision surgical tools. CNC ensures the implants meet strict dimensional and surface finish requirements, critical for long-term in-body stability and safety.

In industrial and energy sectors, CNC machining plays a vital role in manufacturing titanium parts for chemical processing equipment, offshore platforms, and nuclear power facilities. Titanium’s corrosion resistance and strength under harsh conditions make it ideal for these uses. CNC guarantees the high accuracy and reliability required for such critical components, ensuring safety and long service life.

The Cost and Technical Threshold Behind High Precision

While CNC precision machining offers unmatched accuracy and repeatability, it does come with challenges. First, high-end CNC equipment requires significant investment. Second, machining titanium demands experienced programmers and skilled machinists—human expertise remains indispensable. Third, titanium's abrasive nature leads to faster tool wear, increasing tooling costs and necessitating careful tool management.

Conclusion

To sum up, CNC precision machining is vital for overcoming the challenges of titanium alloy processing. With its unparalleled accuracy and efficiency, CNC enables the full potential of titanium alloys to be realized. Despite the need for higher investment and technical expertise, its benefits—especially in terms of performance, precision, and complex shaping—make CNC an indispensable core technology in aerospace, medical, and industrial sectors. A deep understanding and proper application of CNC machining will further expand titanium’s role in cutting-edge applications. I hope today’s discussion provides you with a clearer, deeper understanding of CNC machining for titanium alloys.