Titanium alloys need the right balance of strength and toughness. If heat treatment isn’t done right, it wastes the material’s potential. So, how can we control this process to achieve the best results?

Heat treatment refines titanium’s microstructure. Through precise heating and cooling, specific properties like strength or toughness can be enhanced—ensuring excellent performance in demanding aerospace, medical, or industrial environments.

Achieving this balance isn’t simple. It requires a deep understanding of both the material and the process. So what exactly is toughness in titanium, and how do different treatments influence it?

What is the Toughness of Titanium Alloy?

Strong materials can sometimes be brittle. Toughness, however, is the ability to resist fracture. In critical applications, this is what often makes or breaks a component’s reliability.

Toughness in titanium alloys refers to their ability to absorb energy and resist breaking—even when flaws are present. It’s essential for components subjected to impact or sudden stress, helping prevent catastrophic failure.

Understanding Toughness vs. Strength

Strength measures how much stress a material can take before deforming. Toughness measures how much energy it can absorb before fracturing. For example, a glass window is strong but not tough—it holds its shape but shatters easily. A rubber band, in contrast, is tough but not strong—it stretches and absorbs energy without breaking.

Toughness is commonly measured using tests like the Charpy impact test, where a notched sample is struck by a pendulum to evaluate energy absorption.

Why Toughness Matters

For parts like aircraft landing gear, engine components, or surgical implants, toughness is crucial. These components often face unexpected loads or stress around imperfections. A tough material won’t snap under such conditions—it will bend or yield slightly, avoiding failure.

| Property | Description | Importance Example |

|---|---|---|

| Strength | Resistance to permanent deformation | Supporting static loads |

| Toughness | Resistance to fracture, energy absorption | Surviving impacts or crack propagation |

| Ductility | Ability to deform without breaking | Forming or shaping components |

I once worked on a set of aerospace fasteners where strength was a top priority. But to prevent brittle failures under vibration, we also had to retain a minimum level of toughness—balancing both was critical.

Which Heat Treatment Enhances Toughness the Most?

Not all heat treatments improve toughness—some actually sacrifice it for greater strength. So which method should be used when toughness is the primary requirement?

Annealing—especially Beta Annealing—is most effective at enhancing toughness in titanium alloys. It produces a coarser microstructure that helps stop cracks from propagating.

(

"Annealed Titanium Microstructure")

Annealing for Toughness

Annealing involves heating titanium to a specific temperature, holding it there, and cooling it slowly. It relieves internal stress, boosts ductility, and—depending on the method—can improve toughness.

- Recrystallization Annealing heats the alloy below the beta transus temperature. It refines the grain structure, improving ductility and formability but may not significantly boost toughness.

- Beta Annealing goes above the beta transus temperature, fully transforming the structure before controlled cooling. This results in a coarser, lamellar structure that resists crack propagation—ideal for fracture toughness.

- Stress Relief Annealing uses lower temperatures to reduce residual stress. While not directly increasing toughness, it prevents stress-induced cracking and improves overall performance.

| Annealing Type | Temperature Range | Microstructure Effect | Key Benefit | Trade-off |

|---|---|---|---|---|

| Stress Relief | 480–650°C | Reduces internal stress | Stability | Minimal property change |

| Recrystallization | 650–800°C (below transus) | Fine, equiaxed grains | Ductility | Moderate toughness |

| Beta Annealing | >980°C (above transus) | Coarse, lamellar structure | High Toughness | Lower strength/fatigue |

For parts where fracture toughness is critical, beta annealing is usually the preferred option, even with its minor strength reduction.

How Do You Heat Treat Titanium and Its Alloys Properly?

Heat treating titanium isn’t guesswork—it demands precision. Even small errors can lead to performance issues or failure. What steps are essential?

Proper heat treatment requires thorough cleaning, uniform heating in a vacuum or inert gas, precise temperature control, and appropriate cooling to achieve the target properties.

The Core Heat Treatment Steps

- Cleaning: Titanium surfaces must be spotless. Grease or residue can cause contamination at high temperatures, forming a brittle “alpha case.”

- Loading: Components should be positioned for even heating and to avoid distortion.

- Atmosphere Control: Titanium reacts with oxygen, nitrogen, and hydrogen when hot. Heat treatment must take place in a high vacuum (<10⁻⁴ torr) or inert gas (like argon) to prevent surface degradation.

- Heating & Soaking: Parts are heated evenly and held at temperature long enough for metallurgical changes to occur throughout the cross-section.

- Cooling: Cooling rate determines the final microstructure.

- Fast cooling (e.g., water quench) locks in specific structures.

- Moderate cooling (e.g., air cooling) is typical for annealing.

- Slow cooling (e.g., furnace cooling) offers maximum stress relief.

Each alloy—whether it’s Ti-6Al-4V or commercially pure Grade 2 titanium—requires its own precise treatment plan. Following standards like AMS and ASTM ensures consistency and quality.

What Heat Treatments Make Titanium Stronger?

Sometimes the goal is peak strength, even if toughness drops a bit. How do we achieve maximum strength through heat treatment?

Solution Treatment and Aging (STA) significantly increases the strength of titanium alloys, especially alpha-beta alloys like Ti-6Al-4V.

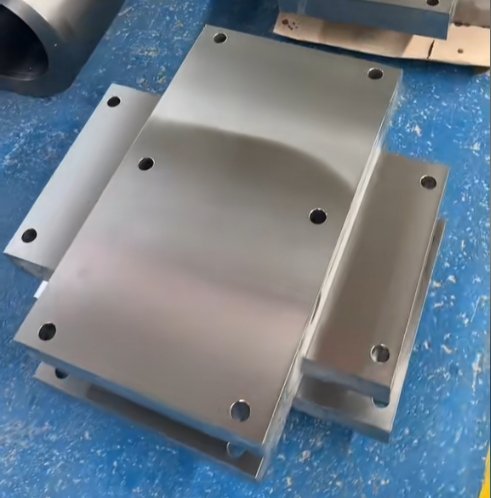

(

"Solution treated products")

Strengthening Through STA

The STA process, also known as precipitation hardening, is ideal for alpha-beta and beta titanium alloys.

- Solution Treatment: The material is heated to the high alpha-beta phase region (~900–950°C for Ti-6Al-4V), dissolving alloying elements into the beta phase.

- Quenching: Rapid cooling (usually water) traps these elements in an unstable phase.

- Aging: The part is reheated to a lower temperature (~480–600°C) and held for hours. This allows fine alpha particles to precipitate, which hinder dislocation movement and boost strength.

| Treatment Stage | Purpose | Temperature (Ti-6Al-4V) | Effect |

|---|---|---|---|

| Solution Treating | Dissolve alloying elements | ~900–950°C | Prepares structure for aging |

| Quenching | Lock in unstable phase | Rapid (water) | Prevents premature precipitation |

| Aging | Form strengthening particles | ~480–600°C | Increases strength and hardness |

STA treatment delivers high strength but usually lowers ductility and toughness compared to annealed material. The trade-off must be carefully weighed based on the part’s performance needs.

Conclusion

Heat treatment is the key to unlocking titanium's full potential. Whether you’re optimizing for fracture resistance or maximum strength, choosing the right method—annealing for toughness or STA for strength—and executing it with precision is critical. Temperature, time, and atmosphere must all be carefully controlled to get it right.