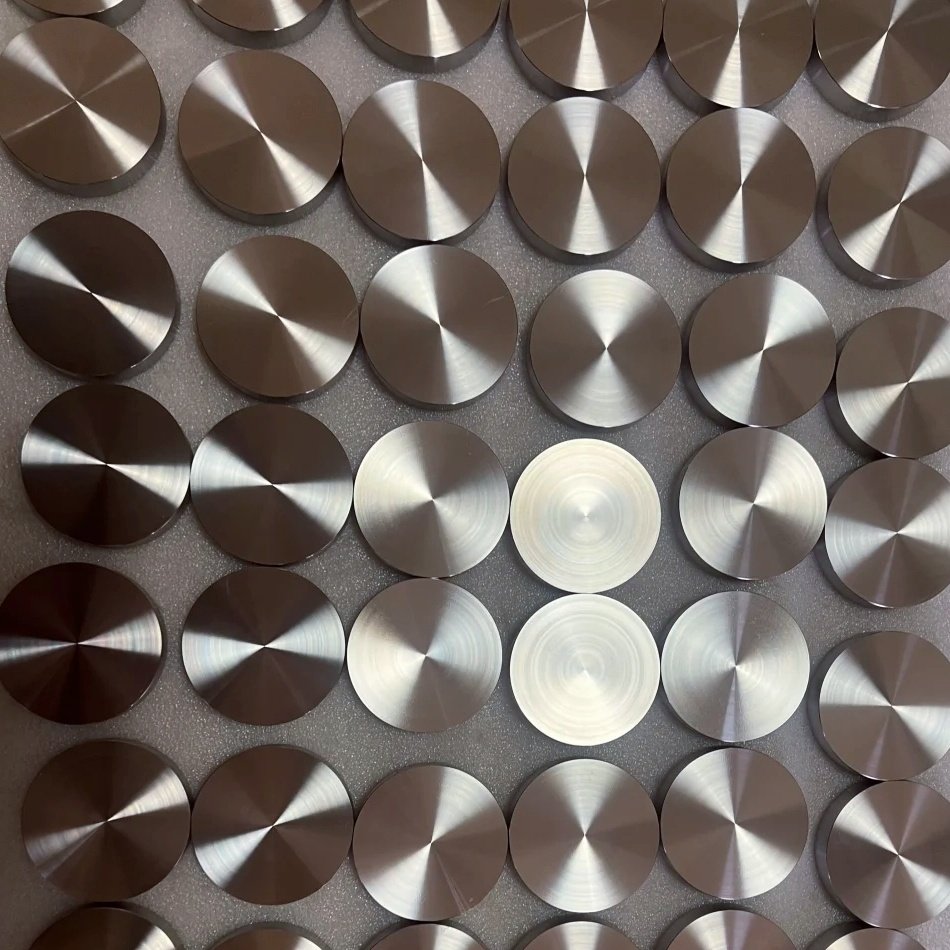

Hello everyone, this is Aria. If you're interested in medical materials, you’re likely already familiar with titanium alloys. As the “star student” of medical devices and implants, titanium is known for its excellent biocompatibility with the human body, high strength-to-weight ratio, and impressive corrosion resistance. These traits have made it essential in orthopedics, dentistry, cardiovascular implants, and precision surgical instruments. However, having a high-performance material alone isn’t enough—especially in applications where safety and reliability are paramount. In such cases, the surface condition of titanium alloys—how smooth, stable, and clean they are—plays a vital role in performance, long-term reliability, and overall lifespan.

Sometimes, it’s this very “skin” of the titanium component that determines whether an implant functions stably for years or whether a surgical instrument operates safely and efficiently. To optimize this surface, one precision surface treatment technique is gaining increasing attention: mirror polishing. Let’s dive into how this technique takes titanium alloy medical products to the next level.

Mirror Polishing: Precision Engineering Beyond Aesthetics

Mirror polishing isn’t simply about making the surface shiny—it’s a sophisticated process designed to reduce surface roughness to a microscopic or even nanometric level (Ra values far below 0.05 µm). The goal is to eliminate micro-peaks, scratches, tool marks, and other imperfections, ultimately producing a highly reflective, smooth finish.

There are several main techniques used to achieve this effect:

- Mechanical Polishing: The traditional method, using abrasives from coarse to fine (such as diamond paste or silicon dioxide suspensions) with polishing wheels or pads to smooth the surface step by step.

- Chemical Polishing: Specific chemical solutions selectively dissolve microscopic surface irregularities, naturally flattening the surface.

- Electropolishing: In an electrolytic environment, the titanium alloy acts as an anode and undergoes controlled anodic dissolution. This is particularly effective for complex-shaped components.

- Chemical Mechanical Polishing (CMP): A hybrid method that combines chemical etching with mechanical abrasion to produce ultra-smooth surfaces with minimal defects at the molecular level.

Titanium's unique properties also make polishing especially challenging. Its high chemical reactivity can lead to undesirable interactions with polishing media, and its relative softness and ductility make it prone to micro-scratching or surface dragging. Moreover, titanium naturally forms a passive TiO₂ oxide layer, which helps with corrosion resistance but can interfere with polishing efficiency. Thus, polishing parameters, abrasives, chemical formulations, and equipment must be carefully selected and precisely controlled—usually by experienced operators using advanced machinery.

Why Mirror Polishing Matters in Titanium Medical Devices

Achieving a mirror-finished titanium surface isn’t just about aesthetics—its functional benefits in medical applications are critical:

-

Orthopedic Implants (e.g., Artificial Joints): For load-bearing and articulating parts like femoral heads or tibial trays, a mirror-polished surface drastically reduces friction and wear. This smooth finish minimizes the generation of wear particles (such as metal ions or debris), which are known to cause bone resorption, implant loosening, and the need for revision surgery. Reducing this risk enhances the implant’s long-term performance and the patient’s quality of life.

-

Dental Implants: For abutments that pass through gum tissue, surface smoothness directly affects soft tissue health and attachment. A mirror-polished surface greatly reduces bacterial plaque accumulation—key to preventing peri-implantitis, a common cause of implant failure. The smooth finish also supports better hygiene for patients and improves long-term tissue integration. In prosthodontics, polished titanium frameworks also enhance porcelain bonding and reduce enamel wear on opposing teeth.

-

Precision Surgical Instruments: For tools used in microsurgery, ophthalmology, neurosurgery, and cardiovascular surgery—such as forceps, scissors, and needle holders—mirror polishing ensures a flawless surface. This not only makes cleaning and sterilization more efficient but also reduces the risk of contamination and infection. Polished tools resist corrosion from body fluids and disinfectants, offering longer service life and high-end precision feel.

-

Cardiovascular and Blood-Contacting Devices: For components like stent connectors and catheter interfaces, an ultra-smooth surface improves hemocompatibility by reducing blood clotting risks and turbulence. While not all devices require full mirror polish, reducing surface roughness is always a top priority. Thanks to their fatigue resistance and durability, titanium alloys remain stable even under high-frequency and high-load operating conditions.

Quality Control and Future Outlook

Given the crucial role of mirror polishing in device performance, quality control is essential. Surface profilometers, Atomic Force Microscopes (AFM), and Scanning Electron Microscopes (SEM) are commonly used to assess parameters like roughness (Ra, Rq, Rz), topography, and micro-defects (scratches, pits, residual stress). Ensuring surface consistency after polishing is a vital part of the production process.

To sum up, mirror polishing of titanium alloys is not just a cosmetic enhancement—it’s a complex technology that integrates materials science, chemistry, physics, and precision engineering. Its true value lies in improving device function: reducing friction and wear, minimizing bacterial adhesion and immune reactions, enhancing sterilizability, and extending product life. As medical technologies evolve and implant standards grow increasingly stringent, surface engineering techniques like mirror polishing will remain key to safer, more effective patient outcomes.