Why Titanium Stands Out in Demanding Applications

Titanium alloys represent the ultimate balance between strength, light weight and corrosion resistance - making them indispensable in aerospace, medical and industrial applications. At Young Things Metal, we've learned through decades of experience that choosing the right titanium grade and form can make or break your project's success.

The Unmatched Advantages of Titanium Alloys:

- Superior strength-to-weight ratio: 60% lighter than steel at comparable strength

- Exceptional corrosion resistance: Performs indefinitely in saltwater and chemical environments

- Biocompatibility: Approved for long-term human implantation

- Temperature versatility: Stable from cryogenic -200°C to 600°C service temperatures

- Long-term reliability: Decades of maintenance-free service even in extreme conditions

Choosing the Right Titanium Alloy: A Practical Guide

Titanium alloys fall into three structural categories, each with distinct advantages:

1. Alpha Alloys (α) - The Corrosion Champions

- Best for: Chemical processing, seawater systems

- Key benefit: Unmatched corrosion resistance

- Trade-off: Moderate strength

- Example: Grade 2 unalloyed titanium for heat exchangers

2. Beta Alloys (β) - The High-Performance Option

- Best for: Aerospace fasteners, orthopedics

- Key benefit: Highest strength potential

- Trade-off: More complex processing

- Example: Ti-10V-2Fe-3Al for landing gear

3. Alpha-Beta Alloys (α+β) - The Balanced Workhorse

- Best for: 80% of industrial applications

- Key benefit: Optimal strength/formability balance

- Trade-off: Requires heat treatment

- Example: Ti-6Al-4V (Grade 5) for airframe components

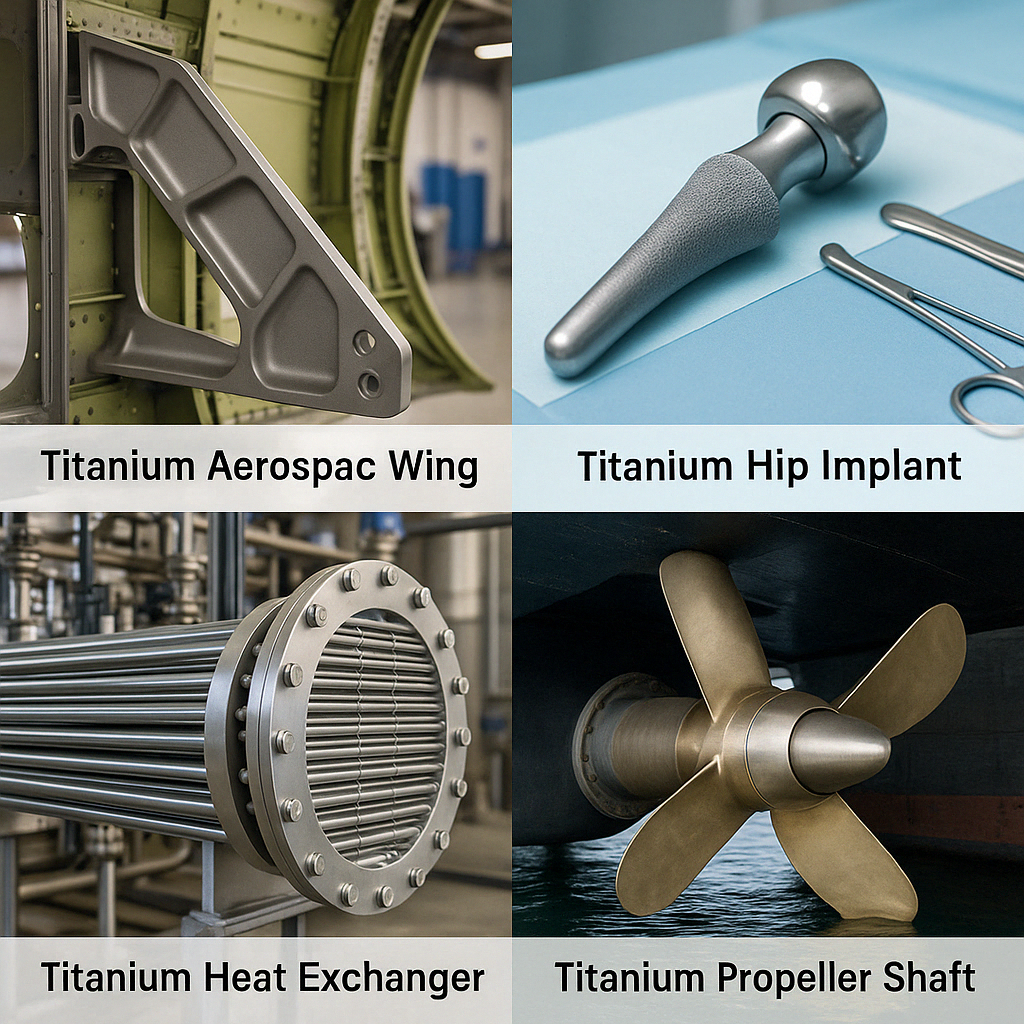

Titanium in Action: Industry-Specific Applications

| Industry | Typical Uses | Why Titanium? |

|---|---|---|

| Aerospace | Airframe structures, engine components | Weight savings = fuel efficiency |

| Medical | Implants, surgical tools | Biocompatibility + imaging compatibility |

| Chemical | Reactors, heat exchangers | No corrosion in acids/chlorides |

| Marine | Propeller shafts, subsea housings | Lifetime service in seawater |

The Future of Titanium Technology

- Advanced Alloy Development: New formulations with improved machinability and reduced stiffness for medical applications

- Additive Manufacturing: Complex 3D-printed structures with internal lattices for weight reduction

- Surface Engineering: Nano-coatings for enhanced wear resistance and osseointegration

- Cost Reduction: Improved production methods bringing titanium to mass-market applications

-

Sustainability: Closed-loop recycling maintaining material properties indefinitely

Why Partner With Young Things Metal?

With 20+ years in titanium supply, we provide more than just metal - we deliver solutions:

- Technical expertise: From grade selection to finishing processes

- Reliable supply chain: Mill-direct materials with full traceability

- Industry-specific knowledge: Aerospace, medical, marine applications

- Value-added services: Testing, certifications, just-in-time delivery

📞 Contact Our Titanium Specialists Today

Looking for a long-term titanium partner that understands your industry?

Reach out to us today for technical support, material specs, or project consultation.

📧 Olivia@titaniumyx.com

📱 WhatsApp: +1 213-254-8005

Titanium isn’t just a material—it's a smarter way to build.

Let Young Things Metal help you take advantage of it.

Share this article

Written by : 钛合金网

Follow us

Table Of Content