Hi again! It’s Aria, your titanium alloy product manager. Last time we explored titanium anodizing, and today I’d love to introduce you to an even more powerful surface treatment technology—Micro-Arc Oxidation (MAO), also known as Plasma Electrolytic Oxidation (PEO). Although it might sound similar to traditional anodizing, MAO differs significantly in terms of its working principles, coating characteristics, and application areas. Let’s take a closer look at how MAO unlocks extraordinary performance for titanium alloys.

What Is MAO? A "Hardcore" Surface Upgrade

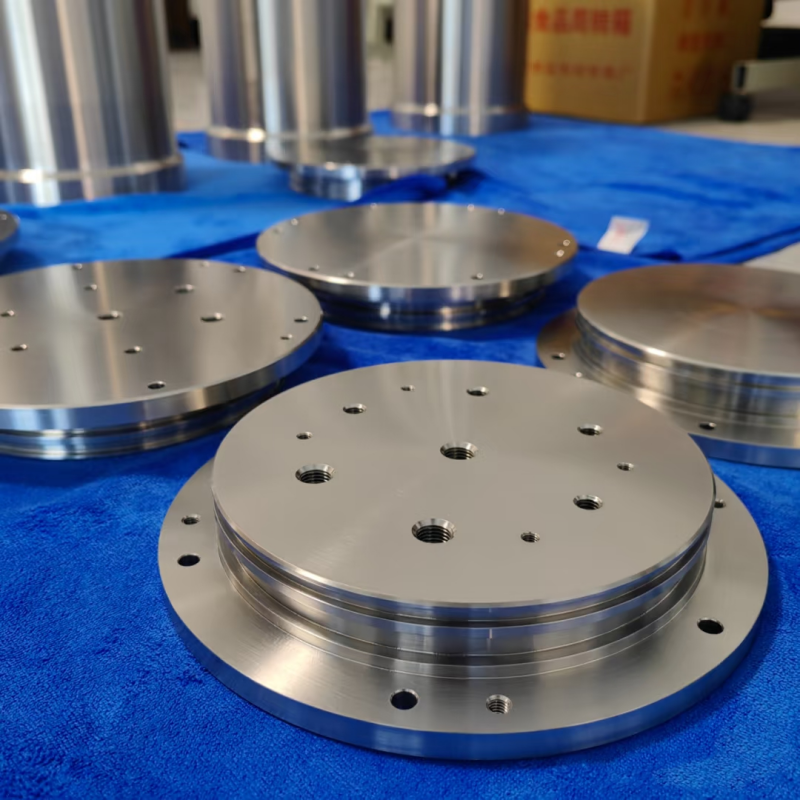

MAO is a high-voltage electrochemical process. It operates at extremely high voltages, triggering arc discharges on the metal surface, which results in the growth of a thick, ceramic-like oxide film. The coating thickness can reach from tens to hundreds of microns—far beyond traditional anodizing. Compared to the thinner films from regular anodizing, MAO coatings are thicker, more compact, and significantly tougher, making them ideal for corrosive and high-wear environments.

Superior Corrosion Resistance: A Shield for Extreme Environments

Titanium alloys are already known for their corrosion resistance, but MAO coatings take that to a new level. The thicker, more robust oxide layer offers enhanced protection against harsh environments such as seawater, strong acids, and alkaline chemicals.

This makes MAO-treated titanium ideal for marine engineering, deep-sea exploration, and chemical processing equipment, where corrosion resistance is mission-critical. For example, MAO-coated components on deep-sea devices or offshore oil platforms show prolonged service life and reduced maintenance needs, even in high-pressure and corrosive environments.

Enhanced Wear Resistance: Performance Under Friction

In addition to corrosion protection, MAO significantly enhances wear resistance. The high-voltage treatment not only increases the oxide layer's thickness but also boosts its hardness. This makes MAO-coated titanium suitable for frequent contact or friction-intensive applications—like ship components, mechanical casings, or structural parts in the automotive industry.

Even under heavy load, the MAO layer resists surface wear, maintaining long-term operational stability and performance.

Beauty Meets Function: Durable, Vivid Colors

One eye-catching advantage of MAO is its ability to produce color effects due to light interference caused by variations in the oxide layer’s thickness and structure. These colors aren’t painted on—they’re part of the oxide film itself.

Depending on the process parameters, the titanium surface can show gold, blue, purple, and other metallic tones. These vibrant finishes are highly durable and fade-resistant. As a result, MAO-treated titanium is often used in luxury design products, outdoor gear, and premium bicycle frames—adding both design flair and commercial appeal.

Unique Advantages in the Medical Field

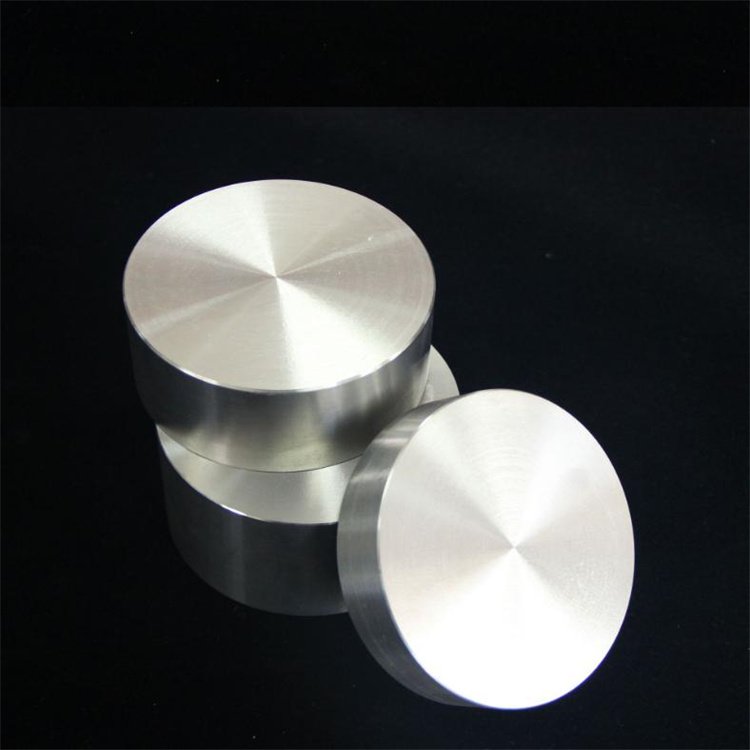

While anodizing is commonly used in medical applications to enhance biocompatibility and corrosion resistance, MAO offers even greater benefits. The MAO oxide layer is thicker, harder, and more wear-resistant, making it ideal for long-term medical implants.

In orthopedics and dentistry, MAO can produce nano-structured oxide films that improve cellular attachment and bone cell proliferation. This accelerates osseointegration, helping implants bond faster and more securely with bone tissue—outperforming the thinner coatings of traditional anodizing.

Additionally, the porous structure of the MAO layer can act as a drug delivery system, embedding antibiotics or growth factors for slow release, further enhancing healing and tissue regeneration. Due to its durability, MAO is particularly suitable for high-load implants like artificial joints and spinal devices, offering superior long-term performance in terms of both wear resistance and biological safety.

Conclusion: MAO as a Comprehensive Upgrade for Titanium Alloys

Micro-Arc Oxidation takes titanium alloys to a whole new level. It enhances corrosion and wear resistance, delivers stunning aesthetics, and improves biocompatibility for medical applications.

With its wide-ranging benefits, MAO is a versatile, high-performance solution for applications in aerospace, marine engineering, chemical processing, and medicine. It’s the all-rounder of titanium surface treatments.

I hope today’s post gave you a deeper understanding of MAO and its unique advantages. In the future, we’ll continue exploring more innovative technologies and applications of titanium alloys. Stay tuned for more exciting breakthroughs!

Share this article

Written by : 钛合金网

Follow us

Table Of Content

- What Is MAO? A "Hardcore" Surface Upgrade

- Superior Corrosion Resistance: A Shield for Extreme Environments

- Enhanced Wear Resistance: Performance Under Friction

- Beauty Meets Function: Durable, Vivid Colors

- Unique Advantages in the Medical Field

- Conclusion: MAO as a Comprehensive Upgrade for Titanium Alloys