Introduction

In today’s fast-paced business environment, an efficient supply chain is crucial for maintaining a competitive edge, especially when dealing with critical materials like titanium alloys. Streamlining your titanium supply chain not only enhances operational efficiency but also significantly reduces costs, driving profitability and customer satisfaction. Whether you're a small business or a large enterprise, optimizing your titanium supply chain can lead to substantial improvements in your bottom line.

This comprehensive guide will walk you through key strategies, practical tips, and real-world examples tailored specifically for titanium procurement. From selecting reliable suppliers to ensuring the quality and traceability of your titanium alloys, these insights are designed to help you, as an overseas purchaser, navigate the complexities of the titanium market and streamline your supply chain effectively.

Understanding the Importance of an Efficient Supply Chain

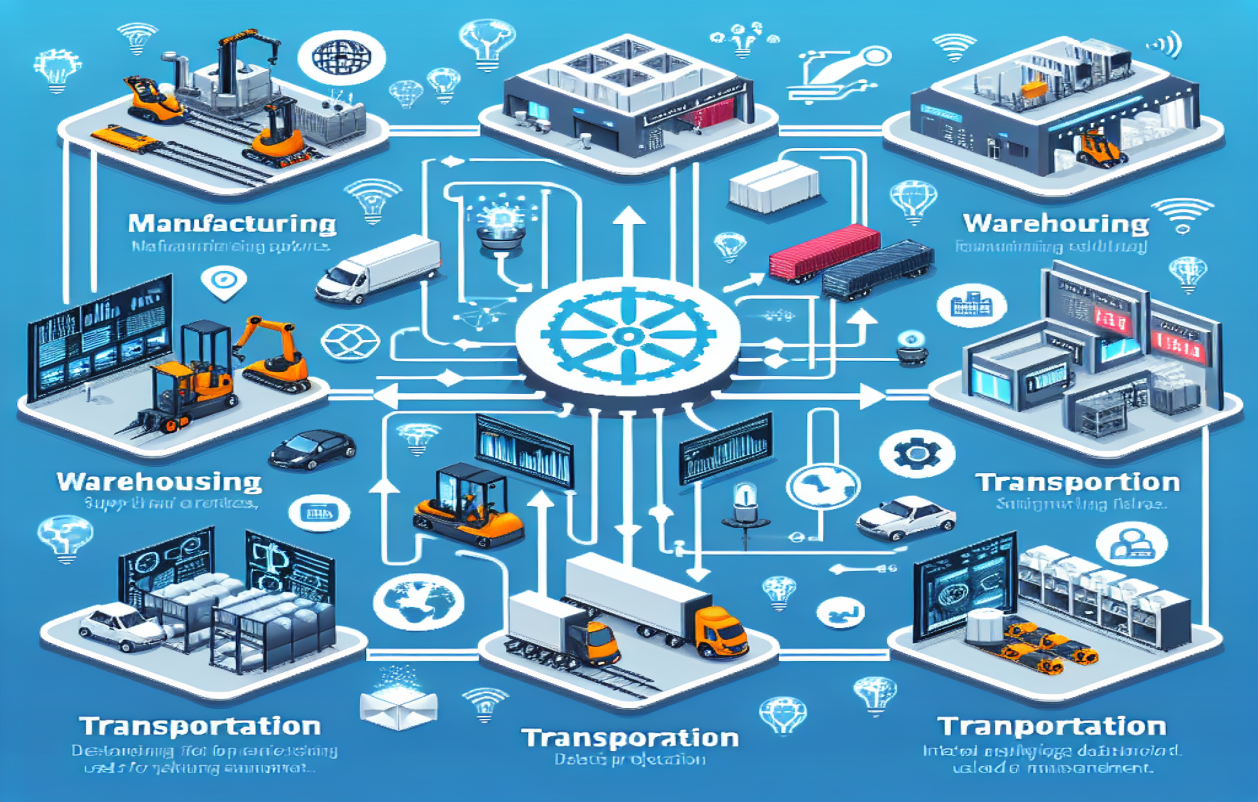

An efficient supply chain ensures that products are delivered to customers promptly, inventory levels are optimized, and operational costs are minimized. It involves the seamless integration of suppliers, manufacturers, warehouses, and retailers, facilitating smooth transitions at every stage. By streamlining your supply chain, you can reduce lead times, improve quality control, and enhance customer satisfaction, all while cutting costs.

When it comes to sourcing critical materials like titanium alloys, the benefits of a streamlined supply chain become even more evident. A direct and efficient supply chain can significantly enhance the quality and reliability of the materials you receive, which is crucial for industries where precision and safety are paramount.

Consider this real-world example: The recent issue with Boeing's "Starliner" spacecraft, where two American astronauts were stranded on the International Space Station for over half a month due to a delayed return, underscores the risks of a complex supply chain. The problem arose because Italy purchased titanium alloys from both China and India. While Italy kept the Chinese-manufactured titanium for itself, it sold the Indian-manufactured titanium to the United States. Unfortunately, in an effort to cut costs, the Indian supplier replaced the titanium with aluminum alloy, and the U.S. mistakenly used this aluminum alloy in the spacecraft, believing it was titanium.

Had the U.S. simplified its supply chain by sourcing titanium directly from China, this costly and dangerous error might have been avoided, ensuring the astronauts’ safe and timely return. This example highlights the critical importance of supply chain efficiency, especially for overseas buyers. By cutting out unnecessary intermediaries and ensuring direct, reliable sources, you can maintain the integrity of your titanium products, avoid costly mistakes, and ultimately protect your business’s reputation and operations.

Key Strategies for Streamlining Your Supply Chain

1. Automate and Integrate Technology

Technology plays a pivotal role in modern supply chain management. Implementing automation and integrating advanced technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) can significantly enhance efficiency. Automation reduces manual errors, speeds up processes, and provides real-time data for better decision-making.

Practical Tips:

- Invest in Warehouse Management Systems (WMS):These systems streamline inventory tracking, order fulfillment, and shipping processes. A WMS can also help in optimizing warehouse space and ensuring that products are stored in a manner that speeds up picking and packing.

- Use AI for Demand Forecasting:AI can analyze historical data to predict future demand, enabling better inventory management. This can help in reducing excess inventory and minimizing stockouts, ensuring that your business can meet customer demand without incurring unnecessary costs.

- Implement IoT Devices:IoT sensors can monitor the condition and location of goods, ensuring timely deliveries and reducing spoilage. For example, IoT-enabled temperature sensors can ensure that perishable goods are kept within the required temperature range throughout their journey.

2. Optimize Inventory Management

Effective inventory management is crucial for reducing costs and avoiding stockouts or overstocking. By maintaining optimal inventory levels, you can ensure that you have the right products in the right quantities at the right time.

Practical Tips:

- Adopt Just-In-Time (JIT) Inventory:JIT minimizes inventory holding costs by receiving goods only when they are needed. This approach can significantly reduce storage costs and decrease the risk of inventory obsolescence.

- Use ABC Analysis:Classify inventory into three categories (A, B, and C) based on their importance and value, and manage them accordingly. Focus on managing A items more closely as they represent the highest value.

- Implement Vendor-Managed Inventory (VMI):Allow suppliers to manage inventory levels, reducing the burden on your internal resources. This can lead to better inventory turnover and decreased stockholding costs.

- Cycle Counting:Regularly count a portion of your inventory to ensure accuracy and identify any discrepancies early. This ongoing process helps in maintaining inventory accuracy without the need for disruptive full inventory counts.

3. Foster Strong Supplier Relationships

Building strong relationships with suppliers is essential for a streamlined supply chain. Collaborative partnerships with suppliers can lead to better communication, improved quality, and more favorable terms.

Practical Tips:

- Develop Collaborative Agreements:Work with suppliers on long-term contracts that benefit both parties. These agreements can include shared goals and performance metrics to ensure alignment.

- Conduct Regular Performance Reviews:Assess supplier performance regularly and provide feedback to ensure continuous improvement. This helps in maintaining high standards and addressing any issues promptly.

- Leverage Supplier Expertise:Involve suppliers in product development and process improvement initiatives. Suppliers can offer valuable insights and innovations that can enhance your supply chain.

- Supplier Development Programs:Invest in training and development programs for your suppliers to help them improve their processes and capabilities. This can lead to better quality and reliability in your supply chain.

4. Enhance Transportation and Logistics

Transportation and logistics are critical components of the supply chain. Optimizing these areas can lead to significant cost savings and improved delivery times.

Practical Tips:

- Use Transportation Management Systems (TMS):TMS can optimize route planning, reduce fuel consumption, and improve delivery efficiency. These systems can also provide real-time tracking and visibility into shipments.

- Consolidate Shipments:Combining smaller shipments into larger ones can reduce transportation costs and improve efficiency. This can be achieved through better coordination with suppliers and customers.

- Evaluate Carrier Performance:Regularly assess carrier performance and negotiate better rates based on volume and reliability. Building strong relationships with carriers can also lead to more flexible and reliable services.

- Optimize Packaging:Use packaging that maximizes space and minimizes weight to reduce shipping costs. Additionally, consider using reusable or recyclable packaging to enhance sustainability.

5. Implement Lean Principles

Lean principles focus on eliminating waste and improving efficiency. By adopting lean methodologies, you can streamline processes, reduce costs, and enhance overall productivity.

Practical Tips:

- Conduct Value Stream Mapping (VSM):Identify and eliminate non-value-added activities in your supply chain processes. This helps in streamlining workflows and reducing bottlenecks.

- Apply 5S Methodology:Organize the workplace to improve efficiency and safety (Sort, Set in order, Shine, Standardize, Sustain). This methodology can lead to a more organized and productive work environment.

- Use Kaizen:Implement continuous improvement initiatives to enhance processes regularly. Encourage employees to identify areas for improvement and suggest solutions.

- Standard Work:Develop standardized procedures for common tasks to ensure consistency and reduce variability in processes.

6. Utilize Data Analytics

Data analytics provide valuable insights into supply chain performance. By leveraging data, you can identify trends, forecast demand, and make informed decisions.

Practical Tips:

- Implement Advanced Analytics Tools:Use tools like predictive analytics and business intelligence software to analyze supply chain data. These tools can help in identifying patterns and making data-driven decisions.

- Monitor Key Performance Indicators (KPIs):Track KPIs such as order accuracy, lead times, and inventory turnover to gauge performance. Regularly reviewing these metrics can help in identifying areas for improvement.

- Conduct Root Cause Analysis:Identify the underlying causes of supply chain issues and address them proactively. This approach helps in resolving problems at their source and preventing recurrence.

- Scenario Planning:Use data analytics to model different scenarios and assess their impact on your supply chain. This can help in preparing for potential disruptions and making contingency plans.

Real-World Examples

Example 1: Walmart’s Supply Chain Optimization

Walmart, one of the largest retailers globally, is renowned for its efficient supply chain. By implementing advanced technologies like RFID for inventory tracking and TMS for optimizing transportation routes, Walmart has significantly reduced costs and improved delivery times. Their focus on strong supplier relationships and sustainability initiatives has further streamlined their operations. Walmart's continuous investment in supply chain innovation has set a benchmark for the retail industry.

Conclusion

Streamlining your supply chain, especially when it comes to sourcing critical materials like titanium alloys, is your ticket to smoother operations and cost savings. Whether it's automating procurement, fostering strong supplier relationships, or embracing data-driven decisions, these strategies will keep your business running like a well-oiled machine. And hey, while you're optimizing, why not let us handle your titanium needs? We've got the quality, reliability, and just the right amount of charm to make your supply chain shine. Let's make your next move in titanium sourcing a breeze!Feel free to contact us anytime!

Share this article

Written by : 钛合金网

Follow us

Table Of Content