Hello everyone, I’m Olivia, your procurement assistant. It’s been a while since we last spoke because I’ve been incredibly busy lately! Many of you know that I mainly focus on exporting titanium alloy profiles, sheets, pipes, and fasteners, with occasional work in titanium anode mesh exports. However, recently, a number of foreign clients have reached out to me, asking for help sourcing “black titanium mesh scrap, titanium anode scrap, or black titanium plate scrap.” This caught me off guard, as I’ve always concentrated on exporting brand-new products. So why are so many clients suddenly interested in scrap materials? Today, I’ll explain what’s driving this trend.

Though the names may vary, they all refer to the same thing—titanium anode mesh, widely used in the electrolysis and electroplating industries. Its corrosion resistance and durability make it valuable for various industrial applications. However, over time, the mesh surface can degrade or become contaminated, requiring replacement. The replaced anode mesh then turns into what we call “scrap.” But why has this scrap become so sought after, and why is it challenging to find sellers? Let me break it down for you.

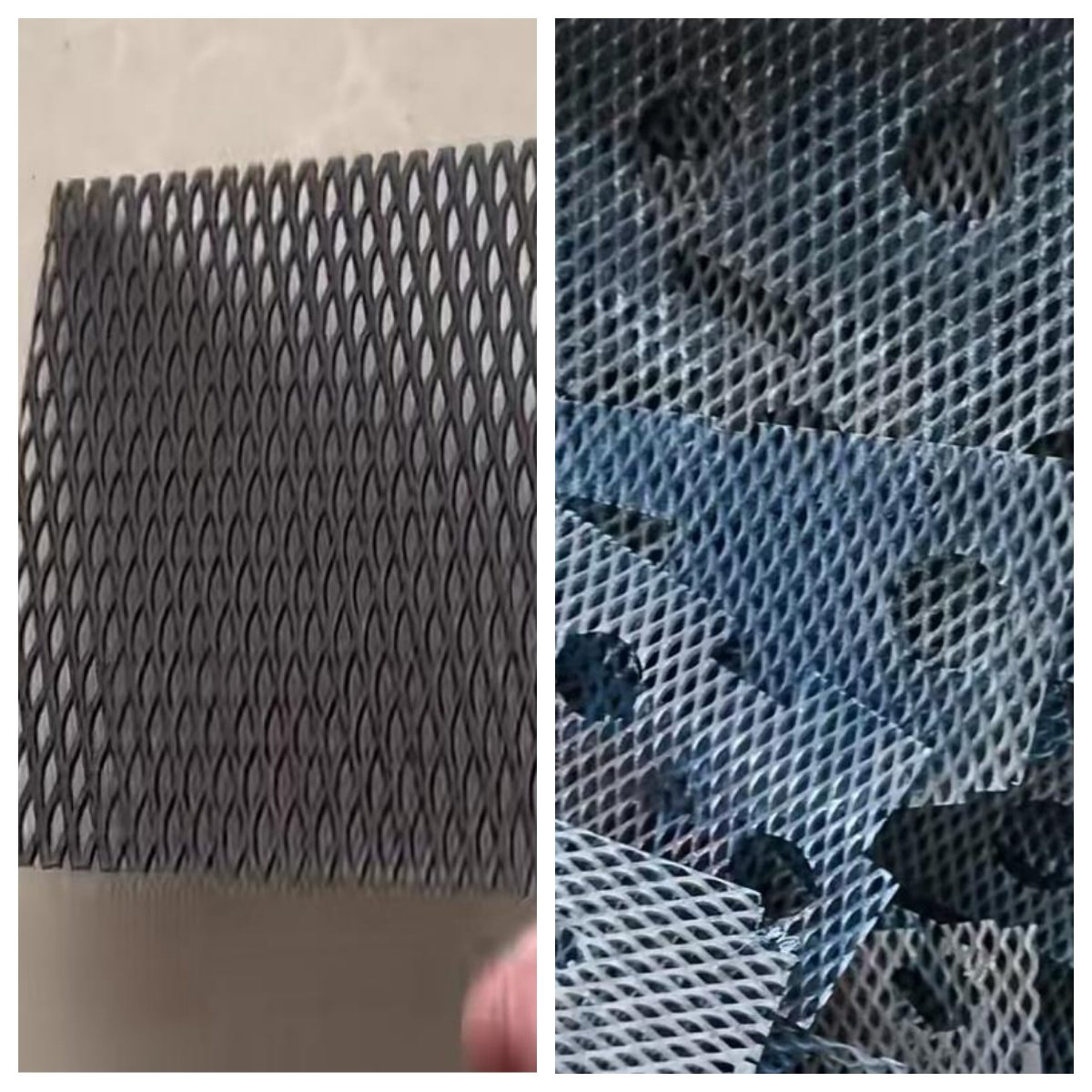

Let’s clarify this with an example of iridium-coated titanium anode mesh. The black titanium anode mesh in the image contains 20.4% iridium. Typically, one kilogram of this titanium anode mesh yields 5-10 grams of iridium.Based on today’s market price, ranging from $149.02 to $149.66 per gram, one kilogram of mesh yielding 8 grams of iridium results in a purchase price of $281.94 per kilogram. The leftover titanium scrap is valued at $5.6 per kilogram.

Here’s how the profit would be calculated:

Profit = Sale price of extracted precious metals + Value of remaining titanium scrap – Cost of purchasing the scrap – Refining costs

Profit = 8 grams of iridium × $149.2 + $5.6 – $281.94 = $917.2 (excluding refining costs).

Therefore, if you plan to import this type of titanium anode scrap, your offer must at least match or exceed $917.2 per kilogram to make it worthwhile for sellers. As this example shows, I don’t recommend importing titanium anode scrap from China if your main goal is to extract precious metals.

Conclusion

If your primary goal in importing titanium anode scrap is to recover precious metals, I strongly advise you to reconsider. You could end up investing significant time and money for minimal returns. However, if your aim is to refurbish and reuse these materials, the story changes. Coatings like iridium, ruthenium, or iridium-ruthenium alloys can be restored and reused. This is done by cleaning, stripping the old coating, and applying a new one.

In summary, I hope this article has helped you understand why “black titanium mesh” is in such high demand and why sourcing scrap from China can be difficult. When considering importing these materials, carefully weigh the costs and benefits. If you’re a procurement professional on a similar project, take time to evaluate the project’s true value. This helps you avoid poor investments and focus on better opportunities. I hope this article has provided valuable insights. If you have any further questions or would like to discuss related topics, feel free to leave a comment. I’m Olivia, and I’ll see you next time!

Share this article

Written by : 钛合金网

Follow us

Table Of Content

Latest articles

February 5, 2025