As an overseas buyer, you’re likely aware of China’s dominant position in the global titanium market. However, navigating the landscape of small batch and custom titanium sourcing can be challenging, especially when dealing with smaller Chinese manufacturers. This guide aims to provide you with in-depth insights and practical strategies to effectively source titanium products from China’s small to medium-sized factories.

Understanding China’s Titanium Industry Landscape:

China’s titanium industry is diverse, with manufacturers ranging from large state-owned enterprises to small, specialized workshops. For small batch and custom orders, your focus should be on small to medium-sized factories, which often offer more flexibility and personalized service.

Key regions for titanium production include:

- Baoji, Shaanxi Province: Known as “Titanium City,” it’s home to numerous specialized titanium manufacturers.

- Panzhihua, Sichuan Province: A hub for titanium sponge production.

- Luoyang, Henan Province: Known for titanium processing and fabrication.

These smaller factories often specialize in specific product types or manufacturing processes. Some may excel in sheet metal fabrication, while others might specialize in precision machining or additive manufacturing of titanium parts.

Identifying Suitable Small to Medium-Sized Suppliers:

Finding the right supplier is crucial. Here are some effective strategies:

a) Industry Directories: Utilize specialized metal industry directories. Many of these are region-specific and can help you identify smaller manufacturers that may not have a strong online presence.

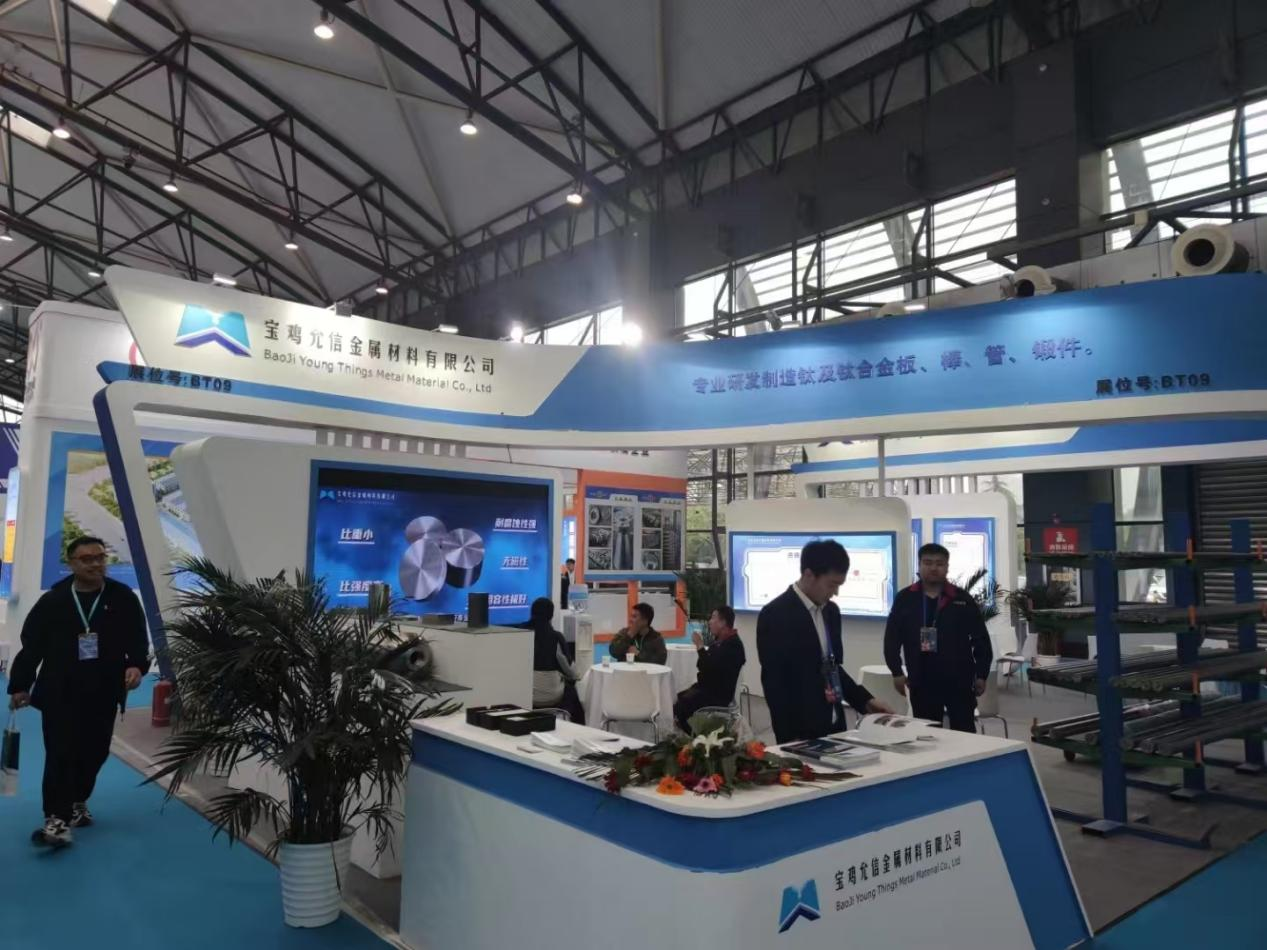

b) Trade Shows: Attend niche trade shows focused on titanium or advanced materials. The China International Titanium Industry Exhibition is an excellent starting point. Smaller, regional shows can also be goldmines for finding specialized manufacturers.

c) Industrial Clusters: Research industrial parks or clusters known for titanium production. Local government websites often provide information about companies operating in these areas.

d) Trade Associations: Engage with associations like the China Nonferrous Metals Industry Association. They can provide valuable insights and connections to smaller, reputable manufacturers.

e) Local Agents: Consider working with a local sourcing agent who specializes in the titanium industry. They often have established relationships with smaller factories and can help navigate language and cultural barriers.

When evaluating potential suppliers, look for:

- Willingness to handle small batch orders

- Flexibility in customization

- Relevant certifications (e.g., ISO 9001, AS9100 for aerospace applications)

- Experience working with international clients

- Specialized equipment suited for your specific needs

Effective Communication Strategies:

Clear communication is vital, especially when dealing with smaller Chinese manufacturers who may have limited experience with international clients.

a) Technical Specifications: Provide detailed, bilingual (English and Chinese) technical drawings and specifications. Include all critical dimensions, tolerances, material grades, and finishing requirements.

b) Quality Standards: Clearly define your quality expectations. Smaller factories may not be familiar with all international standards, so be prepared to explain your requirements in detail.

c) Prototyping Process: For custom parts, establish a clear prototyping and approval process. This might involve several iterations, so patience is key.

d) Use Visual Aids: Whenever possible, use diagrams, photos, or video calls to clarify complex requirements. This can help overcome language barriers and ensure everyone is on the same page.

e) Cultural Considerations: Be aware of Chinese communication styles. Indirect communication is common, so pay attention to subtle cues and be prepared to read between the lines.

Negotiating Terms with Smaller Factories:

Negotiating with smaller Chinese titanium manufacturers requires a nuanced approach:

a) Minimum Order Quantities (MOQs): Smaller factories may be more flexible with MOQs, but be prepared to discuss how you can make smaller orders economically viable for them. This might involve higher unit prices or combining different product types in one order.

b) Pricing Structure: Discuss tiered pricing based on order volume. Even if you’re starting small, showing potential for future growth can lead to better terms.

c) Payment Terms: Smaller factories may require more favorable payment terms due to limited cash flow. Be prepared to discuss options like higher deposits or shorter payment terms, especially for custom orders.

d) Lead Times: Understand that smaller batches or custom orders may require longer lead times. Discuss how rush orders can be accommodated and at what cost.

e) Intellectual Property Protection: For custom designs, clearly outline your IP protection requirements. Smaller factories may not have standardized NDAs, so be prepared to provide your own.

Quality Control for Small Batch and Custom Orders:

Maintaining quality is crucial, especially when dealing with smaller manufacturers who may have less robust quality systems:

a)Material Certifications: Always request material test reports (MTRs) for each batch. For critical applications, consider third-party verification of these reports.

b) In-Process Inspections: For custom or complex parts, consider arranging for in-process inspections. This can be particularly important when working with a new supplier.

c) Final Inspection: For small batches, 100% inspection may be more appropriate than statistical sampling. Discuss this with your supplier and adjust your quality plan accordingly.

d) Third-Party Inspections: Consider using a third-party inspection service, especially if you can’t be on-site yourself. Look for inspectors with specific experience in titanium products.

e) Continuous Improvement: Provide detailed feedback on quality issues. Smaller factories may be more receptive to implementing improvements based on customer feedback.

Logistics and Compliance Considerations:

Importing titanium products from China involves navigating complex regulations:

a) Export Licenses: Be aware that some titanium products may require export licenses from China. Work with your supplier to ensure all necessary paperwork is in order.

b) Shipping Methods: For small batches, air freight might be more economical than sea freight. Discuss consolidation options with your supplier or freight forwarder.

c) Customs Documentation: Ensure all documentation is accurate and complete. This includes commercial invoices, packing lists, certificates of origin, and any specific certifications required for titanium products in your country.

d) Tariffs and Duties: Stay informed about any tariffs or anti-dumping duties that may apply to titanium products from China in your country. These can significantly impact the total cost of your imports.

e) Compliance with End-Use Regulations: If your titanium products are for sensitive applications (e.g., aerospace, defense), ensure your supplier understands and can comply with any end-use certification requirements.

Building Long-Term Relationships:

Cultivating strong relationships with smaller Chinese titanium manufacturers can lead to significant benefits:

a) Regular Communication: Maintain open lines of communication, even during periods when you’re not actively ordering. This helps keep you informed about the supplier’s capabilities and any changes in their business.

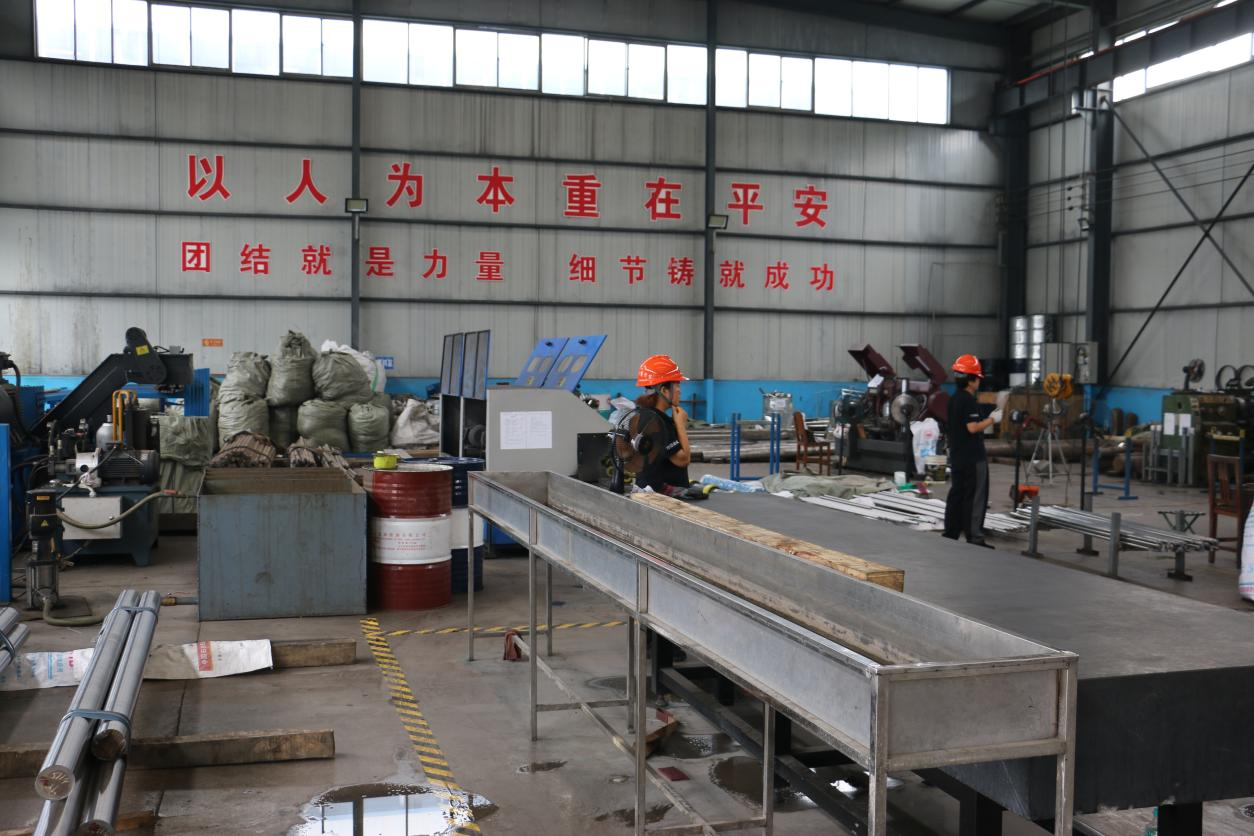

b) Site Visits: Whenever possible, visit your suppliers in person. This is particularly important for smaller factories where personal relationships play a crucial role.

c) Capacity Building: Consider investing in your suppliers’ capabilities. This could involve sharing technical knowledge or even co-investing in specialized equipment for your custom needs.

d) Patience and Understanding: Building trust takes time. Be patient and understanding, especially when working through initial challenges with a new supplier.

Sourcing small batch and custom titanium products from China’s smaller manufacturers offers unique opportunities for personalized service and specialized capabilities. However, it also requires careful navigation of communication challenges, quality control issues, and complex regulations. By following these detailed strategies and maintaining a patient, relationship-focused approach, you can successfully leverage the strengths of China’s small to medium-sized titanium manufacturers to meet your specific needs.

We are a small to medium-sized titanium alloy manufacturing company with our own factory located in the “Titanium Valley.” Our products cover various forms of titanium and titanium alloys, including but not limited to bars, tubes, plates, flanges, fasteners, and more. We also offer custom services. These products are widely used in aerospace, aviation, chemical, medical, sports equipment, and other fields, meeting the demand for high-performance materials in different industries. We are dedicated to providing you with the most suitable products and the highest quality service. Trust us, choose us.

Remember, each sourcing journey is unique. Be prepared to adapt these strategies to your particular requirements and the specific capabilities of your chosen suppliers. With diligence, clear communication, and a commitment to building strong relationships, you can turn the challenges of small batch and custom titanium sourcing from China into a significant competitive advantage for your business.

Share this article

Written by : 钛合金网

Follow us

Table Of Content

Latest articles

February 5, 2025