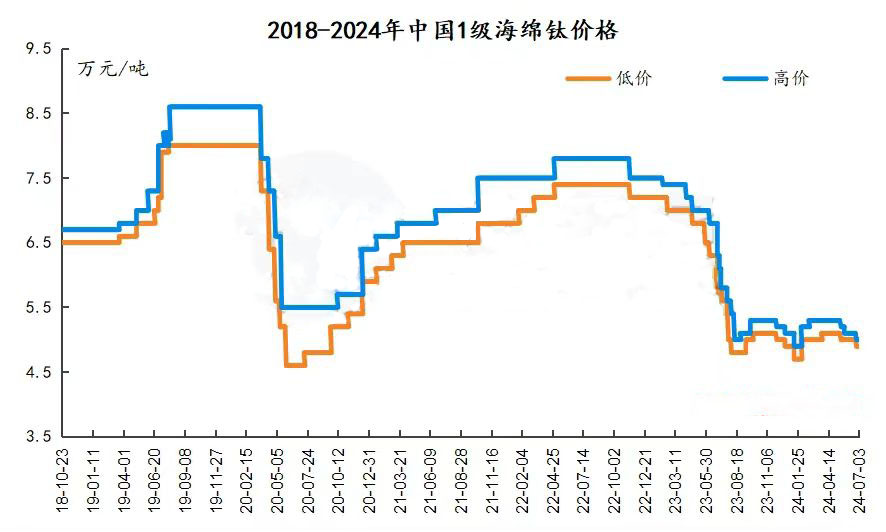

Hello, everyone! It’s been a while. I’m Olivia, your trusty editor. Today, we’re diving into a topic that’s been on everyone’s minds lately—the recent decline in sponge titanium prices. Many of you have been wondering whether this drop will lead to a decrease in the prices of titanium alloy products as well. Initially, I wasn’t planning to dedicate an entire article to this topic, but given the number of inquiries we’ve received, I felt it was essential to address your concerns. So, let’s explore together whether the decline in sponge titanium prices will cause an increase, a decrease, or perhaps even stability in titanium alloy prices.

First, note that sponge titanium is the main raw material for titanium alloys. However, it is just one part of the final product. This means that changes in sponge titanium prices don’t directly cause equal changes in titanium alloy prices. Let me break it down for you:

Titanium alloys are typically composed of sponge titanium combined with other alloying elements. For example, the widely-used Ti-6Al-4V alloy consists of approximately 90% titanium, 6% aluminum, and 4% vanadium. The prices of these elements do not always move in tandem. While sponge titanium prices may drop, the prices of aluminum, vanadium, or other critical elements might rise simultaneously. This complex interplay of raw material costs means that even as sponge titanium prices fall, the final price of titanium alloy products could remain stable or even increase.

Experienced manufacturers understand this dynamic well and have developed strategies to mitigate the impact of raw material price fluctuations. For instance, seasoned factories, like ours, often maintain a strategic inventory of titanium ingots. By regularly purchasing and storing an adequate supply of these ingots, we can shield our customers from sudden cost increases due to fluctuations in raw material prices. This proactive approach helps ensure that the prices we offer remain competitive, even when market conditions are volatile.

Let’s now discuss the impact of inventory and long-term contracts:

Share this article

Written by : 钛合金网

Follow us

Table Of Content

Latest articles

February 5, 2025