Behind every factory is a group of dedicated frontline workers who labor day in and day out. They are not only an essential part of the production process but also the key to ensuring product quality and efficiency. At Young Things Metal Co. Ltd., these frontline workers are like the heart of the factory, keeping operations running smoothly. Their skilled operation of advanced machinery and precise control over each production step are crucial in delivering high-quality titanium products to customers.

This article will briefly introduce the daily work of these employees and the main machinery they use. Through this, we hope to provide a better understanding of the efforts behind the daily production and the hard work these employees contribute.

l.Daily Work of the Workers

-

Initial Cutting – Cai Shifu’s Precision

Cai Shifu is responsible for the initial cutting of titanium ingots, using a high-precision saw. This equipment not only accurately controls the dimensions and weight of the cut but also ensures material uniformity. This step is the foundation for subsequent processes, and Cai Shifu’s precise work ensures that the titanium rods take shape with consistent quality.

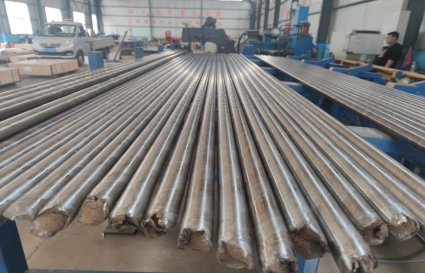

After this step, the cut titanium ingots undergo further processing. Typically, the ingots go through multiple stages of hot and cold processing, such as forging, extrusion, and rolling. These processes gradually transform the ingots into preliminary titanium rods. Although these rods have a basic elongated shape, their surfaces usually carry oxidation scales, and their dimensions and shapes require further adjustment to meet the stringent standards of the final product.

-

Trimming the Ends – Guo Shifu’s Precision Work

After the initial processing, the titanium rods often have irregular ends. Guo Shifu uses a band saw to trim these ends, ensuring that the rods are smooth and even. This work requires a high degree of precision, and the accuracy of the band saw helps Guo Shifu avoid unnecessary material waste while preparing the rods for the next steps.

-

Surface Peeling – Zhang Shifu’s Detailed Work

Next, Zhang Shifu uses a peeling machine to treat the surface of the titanium rods, removing the oxidation layer. The peeling machine not only improves the appearance of the rods but also enhances their mechanical properties. Zhang Shifu’s meticulous operation ensures that the surface of the rods is smooth and uniform, laying a good foundation for subsequent precision processing.

-

Ultrasonic Flaw Detection – Chi Shifu’s Thorough Inspection

Chi Shifu uses an ultrasonic flaw detector, employing water tank flaw detection techniques to check the internal structure of the titanium rods. The ultrasonic flaw detector can detect fine internal defects in the rods, such as cracks or voids, providing crucial quality control for the subsequent processes.

-

Standard Size Cutting – Guo Shifu’s Second Trim

After confirming that there are no flaws, Guo Shifu uses the band saw again to cut the titanium rods to the standard length. Precision is key in this step, and the band saw helps Guo Shifu ensure that each rod meets the expected length standard, preparing them for the following processes.

-

Straightness Inspection and Straightening – Cooperation Between Zhou Shifu and Jiang Shifu

The titanium rods then proceed to the straightness inspection phase. Zhou Shifu and Jiang Shifu use a marble platform to measure the straightness of each rod. By rolling the rods on the marble platform, they observe the smoothness and consistency of the roll to judge straightness. If any rods do not meet the requirements, they use a straightening machine to correct them. The high precision and flatness of the marble platform, along with the stability of the straightening machine, ensure that each rod meets strict straightness standards.

-

End Facing – Yan Shifu’s Precision Processing

After passing the straightness inspection, Yan Shifu uses an end milling machine to process the ends of the titanium rods, making them more neat and symmetrical. The precise machining of the end milling machine not only improves the appearance of the product but also provides convenience for the customer’s use, ensuring that the rods can be perfectly fitted during subsequent processing or use.

-

Polishing and Surface Inspection – The Fine Craftsmanship of Fu Shifu and Yu Shifu

Once the ends of the titanium rods are processed, Fu Shifu and Yu Shifu use a polishing machine to polish them and conduct the first comprehensive surface inspection. The efficiency of the polishing machine ensures the smoothness and uniformity of the rods’ surfaces, and the surface inspection ensures that there are no surface defects.

-

Final Inspection and Packaging – Precision Handling by Zeng Shifu, Chi Shifu, and Shen Shifu

After the titanium rods are polished, Zeng Shifu and Chi Shifu use micrometers and tape measures to conduct sampling inspections of the final product’s diameter, length, and surface, recording all the data to ensure each rod meets customer requirements. Once all inspections are passed, Shen Shifu organizes the team for labeling and secure packaging to ensure that the titanium rods remain intact during transportation.

2.Team Collaboration and Effectiveness

In the production process, handling large orders is a comprehensive test for both the factory and its employees. Producing titanium products requires not only precision in operation but also the ability to deliver large quantities of high-quality products within specified timeframes. This places high demands on the continuous operation of equipment and the collaborative capabilities of the employees.

-

The Challenge of Precision Operations

Under the pressure of large orders, ensuring that each titanium rod meets the required standards for dimensions, straightness, and surface quality is a significant challenge. Employees must remain highly focused, as any small error during prolonged repetitive operations could compromise an entire batch of products. To address this challenge, factory employees work closely together, regularly rotating tasks to avoid fatigue-induced errors. They also routinely check the precision of equipment and make necessary adjustments to ensure that every stage of production meets high standards.

-

Equipment Maintenance

When handling large orders, the continuous operation of machinery increases the risk of wear and tear and equipment failure. To ensure smooth production, the factory has implemented a strict maintenance schedule. During breaks in production, the maintenance team quickly inspects and services key equipment, addressing potential issues before they become problems. Additionally, employees closely monitor the operating conditions of the equipment, reporting any anomalies immediately to ensure that problems are resolved at an early stage.

-

Handling Unexpected Situations

During large-scale production, unexpected situations, such as equipment failure or delays in material supply, are sometimes unavoidable. In the face of these challenges, the factory’s employees demonstrate exceptional teamwork. When an issue arises in one area, the relevant team members quickly coordinate with other departments to respond effectively. For example, if a piece of equipment breaks down, the operators promptly notify the maintenance staff and, while waiting for repairs, adjust the production plan to prioritize other unaffected tasks, ensuring that overall production progress is minimally disrupted.

-

Close Cooperation in Handling Large Orders

Under the pressure of large orders, the factory employees exhibit a strong spirit of collaboration. To ensure smooth production, workers in each process closely coordinate with one another, maintaining clear communication. When one batch of products completes a particular stage, the workers responsible for the next step are already prepared, minimizing unnecessary delays. Additionally, regular team meetings are held to discuss production issues and progress, ensuring that every stage proceeds according to plan.

In facing the challenges of large orders, it is this close cooperation and seamless teamwork that enables the factory to efficiently complete tasks while consistently maintaining high product quality. This is not only a testament to the employees’ skills but also a clear reflection of their collaborative spirit.

3.The Solid Force in Production

Frontline employees have made substantial contributions to improving production efficiency and ensuring product quality at Young Things Metal Co. Ltd. Through their meticulous daily work and cooperation, they effectively ensure the smooth operation of the production process. From handling raw materials to the final packaging of products, the employees consistently follow the factory’s operational guidelines with a strong sense of responsibility. They regularly inspect equipment and adjust production parameters in a timely manner to ensure each stage of production runs smoothly, avoiding bottlenecks.

When faced with high standards from customers, employees demonstrate great flexibility and adaptability. They carefully plan production schedules according to specific order requirements, ensuring tasks are completed within the designated timeframes. Particularly when handling large orders, employees collaborate closely, maintaining clear and effective communication to minimize unnecessary delays.

It is these detailed efforts that ensure the factory maintains stable production levels even when faced with various challenges. The dedication and contributions of the employees not only guarantee the successful completion of orders but also earn the factory long-term trust and cooperation from its clients.

4.Unity and Progress

At Young Things Metal Co. Ltd., employee well-being and teamwork are at the core of the work culture. Employees not only focus on completing their own tasks but also actively assist colleagues in need, fostering a close-knit working relationship. Whether dealing with tight production deadlines or handling daily challenges, everyone works together to overcome difficulties. This atmosphere of mutual support creates a warm and harmonious work environment.

The factory regularly organizes simple yet meaningful team activities, such as group meals and outdoor excursions. These events allow employees to relax outside of work while also strengthening mutual understanding and trust. During these activities, employees can freely exchange ideas, share work experiences, and discuss life stories, further reinforcing team cohesion.

In this positive environment, employees feel a strong sense of trust and support among one another, which drives them to be more engaged in their work. They not only focus on their tasks but are also willing to contribute to the overall goals of the factory. This sense of belonging and collective effort helps employees continuously improve in their work and propels the entire team forward.

5.Conclusion

At Young Things Metal Co. Ltd., the efforts and contributions of every employee lay a solid foundation for the factory’s success. From close collaboration during large orders to mutual support in daily tasks, the team spirit and sense of responsibility displayed by the employees ensure efficient production and high product quality. This, in turn, has earned the factory the trust and long-term cooperation of its clients.

Through continuous optimization of production processes and meeting the high standards set by customers, employees have accumulated valuable experience and actively driven the factory’s growth. Their dedication is reflected not only on the production line but also in their collaboration with colleagues and loyalty to the factory.

Share this article

Written by : 钛合金网

Follow us

Table Of Content

- l.Daily Work of the Workers

- Initial Cutting – Cai Shifu’s Precision

- Trimming the Ends – Guo Shifu’s Precision Work

- Surface Peeling – Zhang Shifu’s Detailed Work

- Ultrasonic Flaw Detection – Chi Shifu’s Thorough Inspection

- Standard Size Cutting – Guo Shifu’s Second Trim

- Straightness Inspection and Straightening – Cooperation Between Zhou Shifu and Jiang Shifu

- End Facing – Yan Shifu’s Precision Processing

- Polishing and Surface Inspection – The Fine Craftsmanship of Fu Shifu and Yu Shifu

- Final Inspection and Packaging – Precision Handling by Zeng Shifu, Chi Shifu, and Shen Shifu

- 2.Team Collaboration and Effectiveness

- 3.The Solid Force in Production

- 4.Unity and Progress

- 5.Conclusion

- l.Daily Work of the Workers

Latest articles

February 5, 2025