eImagine titanium alloys like a piece of chocolate. When we heat chocolate and rapidly cool it, it becomes hard and brittle. The reason is that the sugar molecules in the chocolate don’t have time to rearrange and are frozen in place. Similarly, titanium alloys behave in the same manner. When heated to high temperatures and quickly cooled, the atoms in titanium alloy cannot rearrange properly, forming a fine, tightly packed structure.This fine structure acts like a strong wall, which makes the titanium alloy very hard, often referred to as increased “strength”.

The speed of cooling acts like a magician. It can transform titanium alloys into different forms, making them extremely hard or soft and easily deformable. Slowing the cooling rate allows atoms to rearrange, forming a loosely packed structure. This structure has lower strength compared to the previous one.

At Young Things Metal Co. Ltd., located in Baoji, China, we specialize in producing high-quality titanium alloys that meet international standards. Controlling cooling rates ensures our titanium alloys have superior strength and durability, meeting aerospace, medical, and marine demands.

1.Why is Cooling Rate Important?

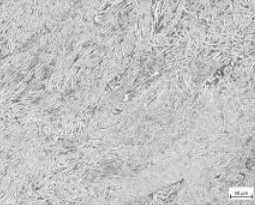

Cooling rate is a key factor that affects material microstructure, strength, toughness, and dynamic failure behavior. Different cooling rates lead to different microstructures. These microstructures significantly alter the failure modes and lifespans of materials under various loads.

1.1 Rapid Cooling

This results in small grains that enhance the material’s strength and hardness but also introduce numerous grain boundaries and dislocations. These defects can act as crack initiators, reducing the material’s toughness, especially under fatigue loading. Excessively rapid cooling may induce residual stress, exacerbating stress concentration and shortening fatigue life. Rapid cooling causes alloy elements to segregate at grain boundaries, forming zones that lead to localized corrosion and stress cracking.

1.2 Slow Cooling

This facilitates grain growth, reducing strength but improving toughness. However, excessively slow cooling may lead to the formation of coarse grains and precipitation phases, increasing susceptibility to creep. Under high-temperature and high-stress conditions, grain boundary sliding and diffusional creep are more likely, accelerating the material’s creep failure.

Cooling rate also significantly affects hydrogen embrittlement. Rapid cooling can cause hydrogen atoms to accumulate at grain boundaries or defects, exacerbating hydrogen embrittlement. Hydrogen atoms can enter the lattice, interact with dislocations, form hydrides, reduce material toughness, and promote crack initiation and propagation.

Cooling rate affects fracture toughness, impact toughness, and oxidation resistance. Rapid cooling reduces toughness, while slow cooling impairs oxidation resistance.The influence of cooling rate on material failure is realized through changes in the material’s microstructure. Different cooling rates result in different grain sizes, dislocation distributions, precipitation phase distributions, etc., all of which affect the material’s strength, toughness, corrosion resistance, and thus its failure behavior.

2.Cooling Rate to Enhance Material Reliability

The key to improving material reliability lies in optimizing the material’s microstructure and composition. Controlling cooling rates, selecting proper mediums, and using heat treatments adjust grain size and phase composition, improving properties. Reducing impurities and surface strengthening also improve reliability. Developing new high-performance alloys is crucial for material reliability. In summary, optimizing cooling, reducing stress, improving purity, and surface treatments enhance reliability for various applications.For a more detailed overview, these measures can be summarized as follows:

- Optimization of Heat Treatment Processes:Use quenching and tempering to control cooling rates for optimal microstructure, improving strength, toughness, and wear resistance.

- Control of Material Composition: Reduce impurities and inclusions, improve purity, and minimize defects to enhance uniformity.

- Surface Treatment Technologies: Use chemical plating and vapor deposition to form protective layers, enhancing corrosion, wear, and fatigue resistance.

- Alloy Design:Introducing specific alloying elements through alloying to improve material properties such as strength, toughness, and high-temperature resistance.

Ultimately, improving material reliability is a systematic process that requires considering material preparation, processing, heat treatment, and other aspects.

3.How Does Cooling Rate Impact Our Lives?

From aircraft soaring in the sky to precise medical instruments, cooling rate silently plays a crucial role behind the scenes. By altering the microstructure of titanium alloys, it imparts new characteristics to materials, profoundly influencing our daily lives.

- Aerospace:Titanium alloy blades in aircraft engines operate under extreme high-temperature and high-pressure conditions. Rapid cooling can produce fine equiaxed grains, enhancing blade strength and fatigue resistance. Slower cooling rates for engine casings produce larger grains, improving toughness and adapting to thermal stress.

- Medical Devices:Artificial joints need to coexist long-term with human bones, making biocompatibility a primary consideration. Controlling cooling rates allows specific grain sizes in titanium alloys, matching their mechanical properties with human bone to reduce rejection. For implants like bone screws, adjusting cooling rates controls strength and toughness to meet clinical needs.

- Sports Equipment:Golf club heads require materials with high strength and low density to increase hitting distance and accuracy. Rapid cooling can produce high-strength, low-density titanium alloys to manufacture lighter and higher-performance golf clubs. Conversely, for bicycle frames, a balance between strength and toughness is necessary for rider safety. By controlling cooling rates, titanium alloy frames with excellent comprehensive performance can be obtained.

- Marine Engineering:Chloride ions in seawater have a strong corrosive effect on metal materials. Rapid cooling creates fine grains in titanium alloys, enhancing resistance to corrosion and cracking, extending marine equipment life. Deep-sea equipment must also consider high-pressure environments. Optimizing cooling processes can produce titanium alloys with excellent pressure resistance properties.

These examples show that cooling rate affects titanium alloy microstructure and directly determines their suitability for different fields. By properly controlling cooling rates, the performance advantages of titanium alloys can be fully realized to meet demanding application requirements.

Titanium alloy forgings for aircraft engines from Young Things Metal Co. Ltd. undergo precise cooling to enhance fatigue resistance and ensure long-term durability under extreme conditions. We control cooling rates for titanium rods in medical devices to optimize biocompatibility and strength, reducing rejection risks and improving outcomes.

4. Achieving a New Breakthrough in Titanium Alloy Tensile Strength

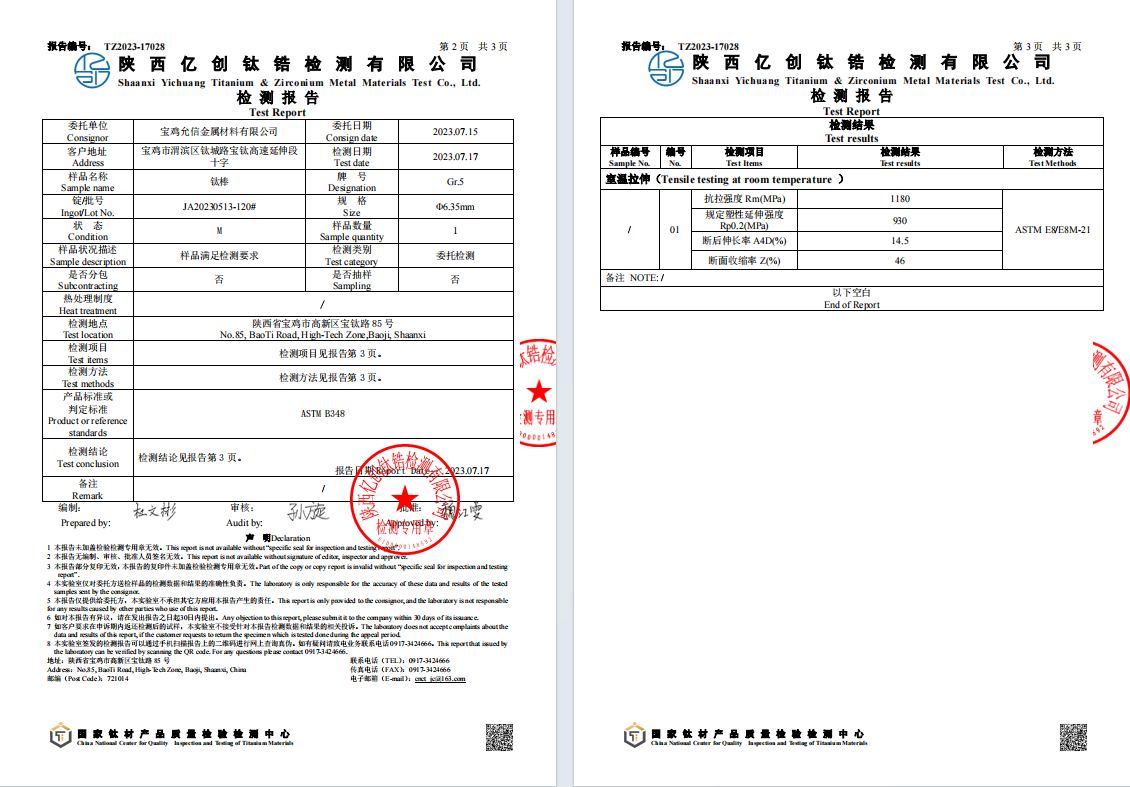

Can we increase the tensile strength of titanium alloys by altering the titanium cooling rate? Yes, by finely controlling cooling and using other heat treatments, tensile strengths can reach 1200 MPa or higher.

The key to achieving a new breakthrough in titanium alloy tensile strength lies in precise control of the cooling process. Through the following steps, we can obtain outstanding performance from titanium alloys:

- Customized Cooling Curves: Designing rational cooling curves is critical to enhancing titanium alloy tensile strength. Precise cooling control adjusts grain size and distribution in titanium alloys and influences phase transformation.Fine equiaxed grains enhance material strength, while specific phase transformation products can bolster material toughness.

- Optimized Cooling Media: Selecting appropriate cooling media is crucial for effective cooling outcomes. Water, oil, gases, and other mediums each possess distinct cooling rates and capabilities. Optimizing cooling media type and temperature allows various cooling methods, from rapid quenching to slow cooling, achieving diverse titanium alloy properties.

- Multi-stage Heat Treatment: Cooling treatment is just one means of enhancing titanium alloy performance. Combining cooling treatments with aging, solution treatment, and other heat treatment processes further optimizes material performance. For example, aging treatments can increase material strength, while solution treatments can enhance material ductility. Through a rational combination of processes, we can obtain titanium alloys with excellent comprehensive performance.

- Advanced Manufacturing Technologies: Traditional casting and forging processes have limitations in preparing complex-shaped titanium alloy components. Advanced manufacturing technologies such as 3D printing can overcome these constraints, facilitating rapid fabrication of complex-shaped parts. Moreover, 3D printing enables precise control over material deposition methods and cooling conditions, further optimizing material performance.

Finely controlling cooling, combined with heat treatments and advanced technologies, enhances titanium alloy tensile strength. This provides high-performance materials for aerospace and medical fields and opens new directions in materials science.

5.What More Can We Do with the “Magic” of Cooling Rates?

The magic of cooling rates extends far beyond these examples. Scientists have discovered that by skillfully controlling cooling rates, titanium alloy performance can be customized.

- Laser Rapid Cooling: Imagine heating a piece of titanium alloy with a laser beam and then rapidly cooling it. Extreme temperature changes alter the internal structure of titanium alloys, creating surface layers with increased wear and corrosion resistance. This technology holds vast potential in the aerospace sector for manufacturing high-temperature-resistant and wear-resistant engine components.

- Plasma Rapid Cooling: Plasma is a high-temperature, high-energy state of matter. Using plasma for rapid cooling of titanium alloys can achieve finer grain structures, thereby enhancing material strength and toughness. This technology has great potential in manufacturing high-performance sports equipment such as golf club heads and bicycle frames.

- Phase Transformation Control: Titanium alloys undergo phase transformation during the cooling process, shifting from one crystal structure to another. Precise cooling control manages phase transformation to achieve specific titanium alloy properties. For example, it can create shape memory titanium alloys used in medical devices and smart materials.

The magic of cooling rates extends far beyond these examples. With continuous advancements in science and technology, we believe cooling rates will play increasingly vital roles in various fields. In 3D printing, controlling cooling rates enables rapid prototyping of titanium alloy parts with complex shapes and excellent performance.

6.Prospects for Future Research on Titanium Cooling rate

With the continuous advancement of technology, the application prospects of titanium alloys are becoming increasingly vast. As a key factor affecting the performance of titanium alloys, research on cooling rate will also deepen in the future. Future research will mainly focus on the following aspects:

6.1 Development of New Cooling Media

- More precise temperature control: Traditional cooling media such as water and oil have certain limitations in controlling cooling rates. In the future, we will develop new cooling media such as nanofluids and phase-change materials. These new media allow precise cooling control, like a temperature regulator, resulting in finer grains and improved performance.

- Diversification of cooling methods: Besides traditional immersion cooling, we can explore spray and laser cooling. These methods meet the cooling needs of titanium alloy parts of various shapes and sizes.

6.2 Innovative Heat Treatment Processes

- More advanced heat sources: Lasers and plasma have concentrated energy and fast heating rates. They rapidly heat and cool titanium alloys, forming surface structures that enhance wear and corrosion resistance.

- Finer local modification:Controlling heat source energy and irradiation time allows heating and cooling specific areas of titanium alloys, improving local properties like forming hard layers to enhance wear resistance.

6.3 Optimization of Processes with Computer Simulation

- Revealing microstructural mysteries:Computer simulation helps us understand microstructural changes in titanium alloys during cooling, such as grain growth and phase transformation.

- Predicting material performance: Simulations can predict titanium alloy performance under different cooling conditions, reducing experiments and improving efficiency.

- Optimization of process parameters: Simulations help optimize heating temperature, cooling rate, and holding time to find the best heat treatment process.

Through in-depth research and innovation in the cooling process, we hope to optimize heat treatment processes to obtain titanium alloys with excellent performance, meeting the urgent needs for high-performance materials in aerospace, medical, and other fields. This research not only expands the application range of titanium alloys and promotes the development of materials science but also provides new ideas for the design of new high-performance materials.Cooling rate is an important factor affecting the performance of titanium alloys. By controlling the cooling rate, we can obtain titanium alloy materials with different performances to meet the needs of different application scenarios.

As a prominent titanium alloy manufacturer, Young Things Metal Co. Ltd. continuously innovates to harness the ‘magic’ of cooling rates. Our commitment to excellence ensures that our titanium products meet the diverse and demanding needs of our global clientele, from aerospace to medical devices. With the ongoing advancement of technology, we remain dedicated to exploring new frontiers in material science and delivering the highest quality titanium alloys to the market. In the future, with the continuous development of science and technology, the application fields of titanium alloys will become more extensive, and the “magic” of cooling rate will bring us more surprises.

Share this article

Written by : 钛合金网

Follow us

Table Of Content