Hey friends, today let’s talk about the “middleman traps” in the titanium industry. Did you know that when buying titanium products, many buyers prefer using middleman suppliers? It’s convenient, saves time, and requires less effort. But there’s a catch—especially with those crafty suppliers. They might smile on the surface, but behind the scenes, they’re setting a trap for you.

One common trick they use is the “silent treatment.” What does that mean? Simply put, they remain silent or vague on key issues, making buyers feel everything’s fine and lowering their guard. They avoid details, dodge crucial clauses, and by the time buyers notice, hidden issues have already surfaced. This silence is often a setup for unfavorable conditions later on.

So, how do you avoid falling into these middleman traps? Don’t worry, I’ve got a few tips for you.

1.Dual Pricing: When Suppliers Serve Both Buyers and Factories

In titanium procurement, experienced middleman suppliers serve as a valuable bridge, especially when language barriers or information gaps exist. They can save you a lot of time and communication costs. These suppliers know the titanium market well, understanding the supply chain and quality needs, providing buyers with valuable support.

But, let’s be honest—the quality of these middlemen varies greatly, and some might leave you feeling disappointed. For instance, some appear to be negotiating a fair price for you, but in reality, they’re squeezing the factory's production costs to pocket the difference. The pricing information is often so unclear that neither the buyer nor the factory can figure out the actual profit margins. So, when choosing a supplier, buyers need to be extra careful to protect their interests.

Let me share a personal experience. In the summer of July 2018, our factory was finally starting to explore the international market—it felt like we were taking baby steps. Every order relied on middleman suppliers, who tightly controlled all customer information. It felt like there was an invisible wall between us and the clients.

Whenever an order issue arose, we had to communicate through them. Even after resolution, we waited for their feedback.And sometimes, errors occur in the message transmission process. It was so frustrating! We were eager to communicate directly with clients. However, the middleman, acting in their own interests, withheld customer information. They constantly came up with excuses, which was extremely frustrating.

What made it worse was their brutal price negotiation tactics. We tried to negotiate, but in the end, we had no choice but to accept their terms. It wasn’t until October of the same year, when we attended the Canton Fair, that we met a buyer from Europe. After talking with him, we discovered the true purchasing price for these products in the European market was shockingly high. It was entirely disproportionate to the prices we had previously sold to the middleman. Our products had been signed off at ridiculously low prices! Then they resold them to buyers? It was pure exploitation, and it made us furious.

When we returned to the factory, there was an overwhelming sense of unease and anxiety. This powerlessness made us realize that lacking direct relationships with customers left us clueless when it came to pricing. This experience made us seriously reflect, and we knew building our own foreign trade team was absolutely necessary!

To avoid exploitation by dual-role suppliers, buyers should be proactive. Building a strong industry network is especially important when purchasing titanium products. Maintaining long-term connections with titanium factories—even if you're not directly buying from them yet—can help. Industry expos and supply chain partners are great ways to learn about factory conditions and baseline market prices. Having this information will help you spot any tricks suppliers might try and strengthen your negotiation power.

2.Fake Factory Tours: When Suppliers Set Up a False Showcase

Some shady suppliers really know how to put on a “factory tour” show! They might lead you to an impressive, fully equipped factory, making you think, “Wow, this is where the titanium products are made.” But in reality, that factory might just be a temporary rental or borrowed space. It could have no connection to the actual production line you're seeking.

We’ve encountered this kind of situation before. A supplier wanted to purchase medical-grade titanium rods, but we didn’t have the production capacity, so we had to work with another factory. To reassure the buyer, they arranged a tour of a professional-looking factory, claiming it would handle the order's critical steps. The truth? That factory had nothing to do with titanium rod production. The entire tour was just a staged show by the supplier, designed to fool the buyer.

So, how do you avoid falling into this middleman trap? First, buyers need to have a clear understanding of their product's production process and use professional methods to verify it. Before the tour, it’s best to have a detailed discussion with your technical team, and even bring them along on the visit. This way, it’s easier to spot any red flags.

When faced with a fake factory tour, buyers can’t just be impressed by appearances. Seeing machines in action is just one aspect. You need to investigate the production process, key equipment, technical specs, materials, and methods. During the tour, take the initiative—don’t let the supplier control the narrative. Ask some technical questions and see how they respond. If their answers are vague or they avoid the topic, that’s a major warning sign. For example, you can ask how they control the temperature during production or how they ensure product quality. If they can’t give you a solid answer, it’s time to be cautious!

3.Multiple Middlemen: Layered Markups Driving Up Costs

When procuring titanium products, be wary of layered markups, especially with multiple middlemen involved. They often hide unnecessary costs through complex pricing strategies. At first, the quote may seem reasonable, even competitive. However, without transparency, buyers often realize the final cost is much higher only after order completion.

I remember one time we were working with an overseas buyer who ordered a batch of custom titanium flanges through a middleman supplier. The initial quote seemed not only fair but also very appealing. However, the supplier didn’t provide a detailed breakdown of the costs. The order proceeded smoothly, and the buyer didn’t question much. But once the order was completed and delivered, they noticed an issue when reviewing the total expenses. As the manufacturer, we found discrepancies in the shipping records and logistics documents, revealing that the supplier had added a lot of extra charges for shipping and packaging that didn’t match the actual operations. They had exploited the buyer’s lack of familiarity with logistics details, sneaking in hidden fees through tricky contract wording.

To avoid this kind of trap, buyers should include a “regular cost audit” step when placing an order. This means after each phase of the order, you thoroughly check the costs to ensure the supplier’s breakdown matches the actual operations. This is especially important for logistics and processing. Buyers should take the initiative to request detailed invoices and supporting documents for every step—nothing should be overlooked. Additionally, you can include a “traceability clause” in the contract, allowing you to trace every cost back to the actual operation. This way, you can cross-check with third parties like factories and logistics companies to make sure everything adds up.

In short, stay sharp, audit regularly, and demand transparency. That way, you’ll make sure every dollar is accounted for, and no one’s sneaking in extra charges!

4.Reselling Second-Hand Goods: The Trap of Unsellable and Repaired Products

Some experienced suppliers are really good at passing off unsellable or refurbished goods as new, high-quality products. They may give you a quality inspection report that looks legitimate, but it could just be a template unrelated to the actual goods. Buyers often lower their guard when the price seems irresistible, believing they’ve scored a great deal—only to receive products riddled with quality issues.

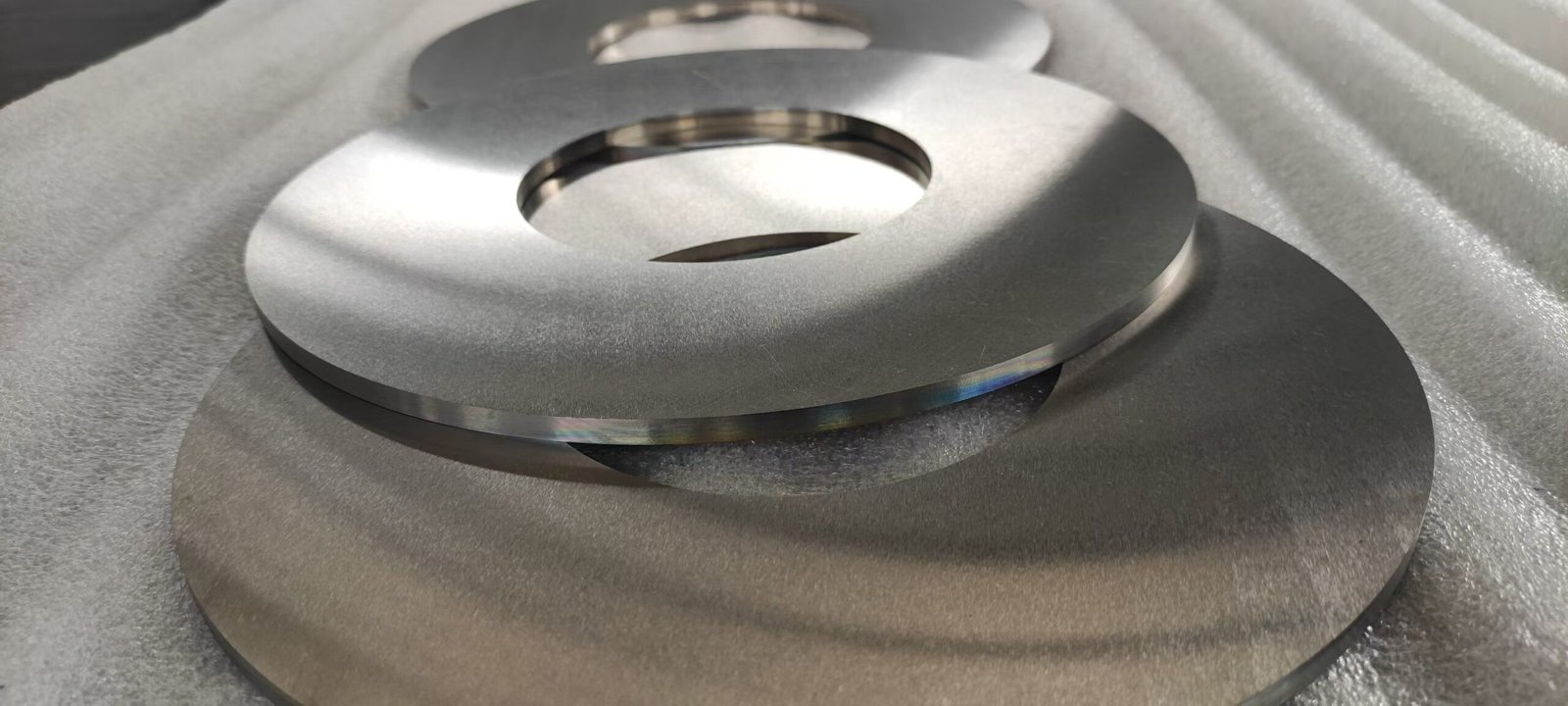

I once heard about a case like this. A buyer purchased a batch of titanium rings through a supplier. The supplier’s inspection report seemed thorough, but when the customer used the rings, they found the strength and precision were substandard. After some investigation, it turned out the titanium rings were actually refurbished products! They’d just been given a quick polish and sold as new. The inspection report? It had been copied and pasted from a previous order and had nothing to do with this batch of goods.

What’s even more surprising is that this supplier had initially approached our factory for a price quote and discussed production and material costs for the same rings. We gave them a quote as requested, but then they suddenly disappeared. We didn’t think much of it until we later heard about this situation. They had likely used our quote to justify buying low-cost, refurbished goods and then sold them as new to the buyer.

To avoid falling into this trap, buyers should try to visit the factory in person and not rely solely on the supplier’s inspection reports. It’s a good idea to ask for an independent third-party inspection before shipping and get an assessment report. Adding a random spot-check clause to the contract is also helpful. You can require the supplier to provide video footage showing the condition of the goods before packaging. While these extra steps may seem like a hassle, they force suppliers to take quality seriously and help buyers avoid falling into these traps!

5.Unclear Product Origins: When Suppliers Hide the Real Source

There’s also a situation where some suppliers mix products from different sources and sell them together, leading to inconsistent quality for the buyer. They also confuse matters by frequently changing the delivery process and concealing details about the actual manufacturer. This leaves buyers in the dark about the true source of the products.

Over lunch one day, a partner of ours shared his experience. His factory produces titanium fittings, and a supplier had bought a batch from him. Later, we heard that the supplier had mixed these fittings with products from other manufacturers and sold them to another buyer. When the buyer started using them, they found that some fittings didn’t meet the corrosion resistance standards. Upon investigation, it turned out that the batch wasn’t from a single manufacturer. Fortunately, our partner’s products were fine, but the issue came from the other sources.

When products are mixed like this, the consequences go beyond just inconsistent performance. The buyer’s entire production schedule could be disrupted, and the risks increase significantly. In the end, the buyer had to find a new supplier and tighten control over product sourcing to ensure clarity about where the goods were coming from.

To prevent this, buyers should proactively require suppliers to specify the origin of each batch in the contract, detailing the manufacturer, production batch, and shipping route. One effective approach is forming a joint purchasing group with other buyers, sharing supply chain insights and experiences. This boosts bargaining power and helps verify product credibility and sourcing through collaboration.

In a joint purchasing model, buyers can collectively require suppliers to provide proof of origin for the goods. By sharing this information, you can ensure that the products you receive come from transparent and reliable sources. This approach is especially helpful for small and medium-sized buyers, reducing the chances of being misled by suppliers. In the end, it helps buyers avoid suppliers hiding the true origin of goods and ensures you’re getting exactly what you paid for!

Conclusion

In the process of purchasing titanium products, working with middleman suppliers can be a double-edged sword. On one hand, they can save time and reduce communication costs. However, some suppliers exploit information gaps and complex supply chains, hiding the actual source or inflating costs to make unfair profits. Sadly, this practice is not uncommon in the industry. To be honest, I’ve personally experienced and heard about all these situations over the years.

By sharing these experiences, I hope to help you better recognize and navigate the potential “middleman traps” that suppliers might set during the procurement process. The purchasing industry is complex and ever-changing, but if you stay vigilant and gather enough industry knowledge, you can minimize risks and ensure every purchase is worth your investment.

So, here’s my advice: always stay sharp when making purchases. Don’t blindly trust flashy quotes and promises. Do your homework, and you’ll be able to stand strong in this highly competitive market. I hope these insights will offer some guidance and help you in your future dealings.

Share this article

Written by : 钛合金网

Follow us

Table Of Content